News Directory

Understanding Angular Contact Ball Bearings: A Comprehensive Guide

I. Introduction to Angular Contact Ball Bearings

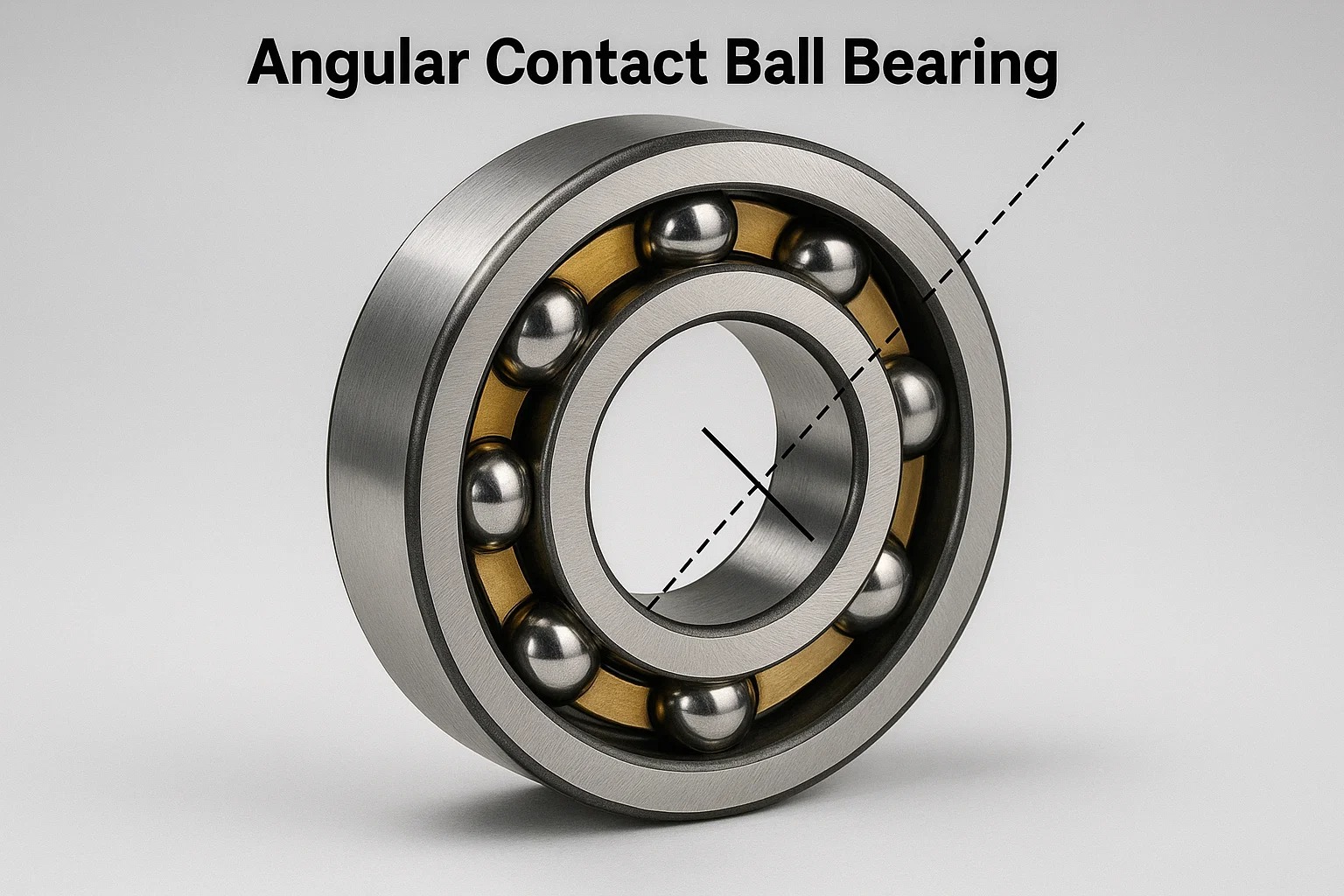

1. What is an Angular Contact Ball Bearing?

An angular contact ball bearing is a specialized type of rolling-element bearing engineered to accommodate both radial and axial loads simultaneously. Unlike deep groove ball bearings, which primarily handle radial loads, angular contact bearings

feature a precisely engineered contact angle between the inner and outer races and the balls. This angle is what allows them to efficiently support axial forces in one direction, in addition to radial forces.

-

Definition and basic function: At its core, an angular contact ball bearing facilitates rotational motion while precisely controlling the relative position of machine components. Its unique design enables it to carry loads acting at an angle to the bearing axis. This capability is crucial in applications where both sideways and thrust forces are present, making them ideal for a variety of industrial and automotive uses.

-

Key features and design characteristics: The defining feature of these bearings is the contact angle, which is the angle between the line connecting the points of contact of the ball with the raceways in the radial plane, and a line perpendicular to the bearing axis. This angle can vary, typically ranging from 15 to 40 degrees, depending on the specific bearing design and intended application. A higher contact angle generally provides greater axial load capacity, while a smaller angle is better suited for high-speed applications with lower axial loads.

| Feature | Description |

|---|---|

| Contact Angle | This is the critical angle that determines the proportion of radial vs. axial load capacity. It typically ranges from 15° (optimized for high speed and lower axial loads) to 40° (optimized for high axial loads). A larger angle means more axial load support. |

| Separable Design | The outer ring is often separable from the inner ring and ball assembly. This design feature simplifies the mounting process and allows for the precise selection of specific internal clearances or the application of preloads during installation. |

| Single-Direction Axial Load | Standard single-row angular contact ball bearings are designed to accommodate axial loads in one direction only. To handle axial loads from both directions, they are typically used in duplex arrangements (paired sets) or as double-row bearings. |

| High Precision | These bearings are manufactured to very tight tolerances, ensuring high running accuracy and minimal runout. This precision is essential for demanding applications, such as those found in machine tool spindles, where even microscopic deviations can impact performance. |

| Rigidity | When properly preloaded, angular contact ball bearings offer exceptionally high stiffness. This minimizes shaft deflection under load and significantly improves overall system performance, particularly in precision-critical applications where stability is paramount. |

2. Why Choose Angular Contact Ball Bearings?

Angular contact ball bearings are selected for their superior performance in specific operating conditions where other bearing types might fall short.

-

Advantages over other bearing types:

- Combined Load Capacity: Their most significant advantage is the ability to efficiently carry a combination of radial and axial loads simultaneously. This sets them apart from deep groove ball bearings (primarily radial) or thrust bearings (primarily axial).

- High Speed Capability: Due to their optimized internal geometry, precise manufacturing, and often lighter cage designs (e.g., polyamide or phenolic resin), they can operate at very high rotational speeds with reduced heat generation.

- High Precision and Rigidity: They offer excellent running accuracy and stiffness, making them ideal for applications requiring precise positioning, minimal deflection, and low vibration. When used in preloaded configurations, they can virtually eliminate internal clearance, leading to exceptional rigidity.

- Versatile Configurations: Available in single-row, double-row, and four-point contact designs, they can also be combined in duplex arrangements (face-to-face, back-to-back, or tandem) to further enhance load capacity, rigidity, and the ability to handle overturning moments.

-

Applications where they excel: These bearings are frequently found in environments demanding high precision, high speeds, and the handling of significant axial forces. Their ability to support combined loads makes them indispensable in various demanding machinery. Common applications include:

- Machine Tool Spindles: Crucial for precise cutting and grinding operations.

- Automotive Transmissions and Wheel Bearings: Handling both vehicle weight and cornering forces.

- Pumps and Compressors: Supporting rotating shafts under combined fluid and mechanical loads.

- Electric Motors: Especially in larger, high-speed designs.

- Robotics: Ensuring accurate and repeatable movement in robotic joints and actuators.

II. Understanding the Design and Functionality

1. How Angular Contact Bearings Work

The operational principle of an angular contact ball bearing hinges on its contact angle, which dictates how loads are distributed and supported.

-

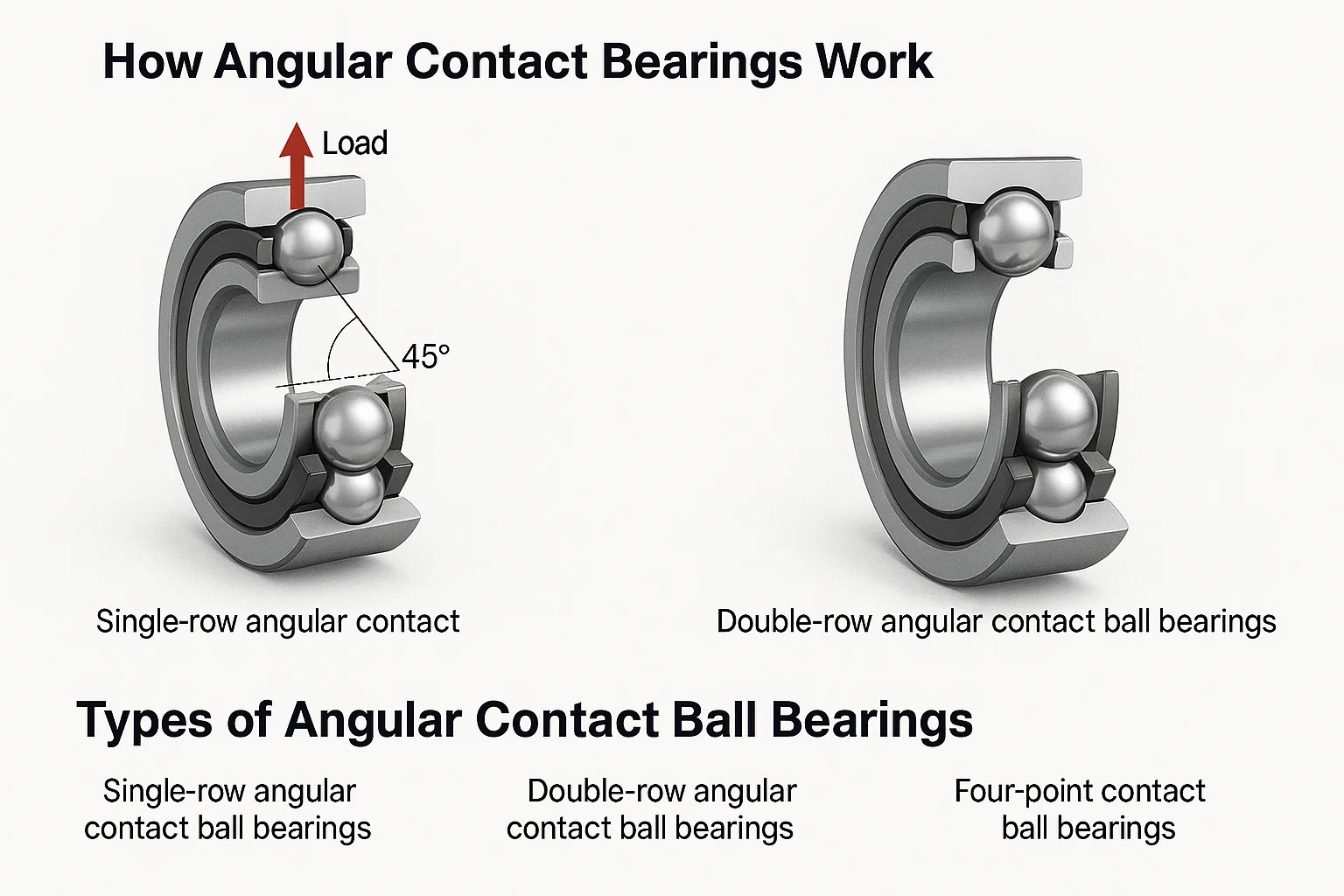

Explanation of the contact angle: When a load, particularly an axial load, is applied to an angular contact ball bearing, the balls are displaced slightly along the raceways. This displacement creates an elliptical contact area between each ball and both the inner and outer raceways. The contact angle is the angle formed by a line through the center of this contact ellipse and a line perpendicular to the bearing's axis of rotation. This angle is fundamental because it determines the proportion of the applied load that is carried axially versus radially. For instance, a larger contact angle (e.g., 40°) means the bearing is better equipped to handle heavier axial loads, while a smaller angle (e.g., 15°) is more suitable for high-speed applications where radial loads are predominant and axial loads are lighter.

-

Load distribution and support: The balls in an angular contact bearing are typically under a preload (either inherent from manufacturing or applied during installation). This preload ensures continuous contact with both raceways, even under varying loads, which is crucial for high rigidity and to prevent skidding of the balls, especially at high speeds. When a combined radial and axial load is applied, the forces are efficiently transmitted through the balls at the contact angle, effectively distributing the stress over a larger area than a purely radial bearing. This design provides superior support and stability under complex loading conditions.

2. Types of Angular Contact Ball Bearings

Angular contact ball bearings come in various configurations, each suited for different load capacities, rigidity requirements, and application demands.

-

Single-row angular contact ball bearings: These are the most common type and can accommodate axial loads in one direction only. Because of this unidirectional axial load capacity, to support axial loads in both directions or to achieve higher rigidity and manage overturning moments, they are often used in duplex arrangements. These involve mounting two single-row bearings together as a matched pair.

Duplex Arrangement Description Key Characteristics Face-to-Face (DF) Two bearings are mounted with their wider faces together, so the contact lines converge towards the bearing axis. Good rigidity, can handle overturning moments, moderate speed capability. Back-to-Back (DB) Two bearings are mounted with their narrower faces together, so the contact lines diverge away from the bearing axis. Maximum rigidity, excellent for handling overturning moments, ideal for high-precision spindles. Tandem (DT) Two bearings are mounted in the same direction, with their contact lines parallel. Designed for extremely high axial load capacity in one direction, load is shared evenly. -

Double-row angular contact ball bearings: These bearings essentially combine two single-row angular contact bearings into a single unit. They are designed to accommodate axial loads in both directions and are often chosen when a compact design with high rigidity is required, eliminating the need for separate duplex arrangements. They are available with various internal designs and contact angles to suit specific needs.

-

Four-point contact ball bearings: These are unique single-row angular contact ball bearings featuring raceways designed to support axial loads in both directions. The inner ring is typically split, and there are four contact points between the balls and the raceways (two on the inner ring, two on the outer ring). This design allows them to handle reversing axial loads while taking up less axial space than two single-row bearings. They are particularly useful for applications with intermittent or alternating axial loads, offering a compact and effective solution.

III. Key Features and Benefits

Angular contact ball bearings are highly valued in various industries due to their distinct performance advantages. Their design allows them to excel in situations demanding high load capacities, exceptional speed, and precise operation.

1. High Load Capacity

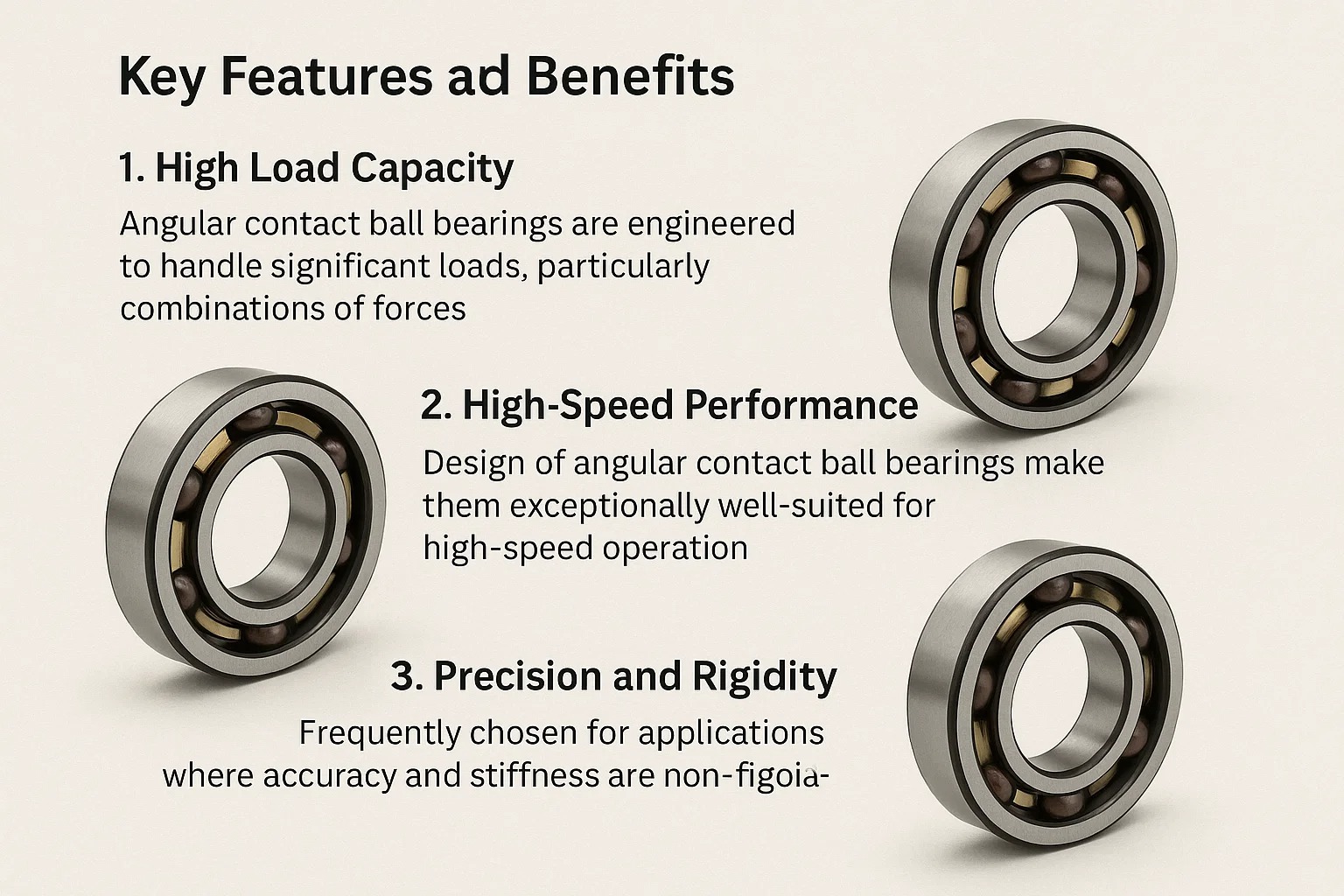

Angular contact ball bearings are engineered to handle significant loads, particularly when these loads are a combination of forces.

-

Axial and radial load handling: The contact angle is the primary factor determining how effectively an angular contact bearing can manage axial and radial loads. Bearings with larger contact angles (e.g., 40 degrees) are optimized for heavier axial loads, making them suitable for applications where significant thrust is present. Conversely, those with smaller contact angles (e.g., 15 degrees) are better suited for higher speeds and applications where radial loads are predominant. This specific design allows for the efficient transmission of forces from the rotating shaft through the balls to the stationary housing or vice versa, distributing stress effectively.

-

Load combinations: One of the greatest strengths of these bearings is their ability to manage combined loads, which are a mix of both radial and axial forces. This is crucial in many industrial applications where machinery experiences complex, multi-directional forces. When two angular contact bearings are mounted in a duplex arrangement (DB or DF), their combined axial load capacity is significantly enhanced, and they gain the ability to support overturning moments, which are critical in applications like machine tool spindles.

2. High-Speed Performance

The design of angular contact ball bearings makes them exceptionally well-suited for high-speed operation, which is a critical requirement in many modern machines.

-

Design considerations for high-speed applications: To minimize heat generation from friction and ensure stability at high RPMs, bearings intended for high-speed applications typically feature smaller contact angles (around 15-25 degrees). They also often incorporate high-precision balls and raceways, along with optimized cage designs. Lighter cage materials, such as phenolic resin or polyamide, are frequently used to reduce mass and inertia, further contributing to lower friction and heat. Additionally, minimal preload is often applied in high-speed designs to prevent excessive heat buildup that could compromise performance and lifespan.

-

Lubrication requirements: Proper lubrication is paramount for maintaining high-speed performance and extending bearing life. This often involves using specialized oils or greases with appropriate viscosity and additives that can withstand high temperatures and shear forces without breaking down. In some extreme high-speed applications, advanced lubrication systems like oil-air lubrication are employed. These systems ensure a constant, precisely metered supply of fresh lubricant while simultaneously helping to carry away heat, effectively cooling the bearing during operation.

3. Precision and Rigidity

Angular contact ball bearings are frequently chosen for applications where accuracy and stiffness are non-negotiable.

-

Applications requiring high accuracy: These bearings are indispensable in applications where precise positioning and minimal runout are paramount. A prime example is machine tool spindles, where the cutting tool must maintain extreme accuracy to produce parts with tight tolerances and high-quality surface finishes. Similarly, in robotic arms, precise joint movement, facilitated by these bearings, is essential for accurate manipulation and assembly tasks.

-

Minimizing runout and deflection: The inherent design of angular contact bearings, especially when used in preloaded duplex arrangements, provides exceptional rigidity. Preloading effectively eliminates internal clearances within the bearing, which translates to minimal deflection under load. This high stiffness and the resulting very low runout (deviation from true rotation) directly lead to enhanced machining accuracy, improved overall system performance, and reduced vibration, contributing to a more stable and reliable operation.

IV. Applications of Angular Contact Ball Bearings

Angular contact ball bearings are found in a wide array of industries and machinery due to their versatility and exceptional performance characteristics. Their ability to handle combined loads, high speeds, and offer high precision makes them indispensable in many critical applications.

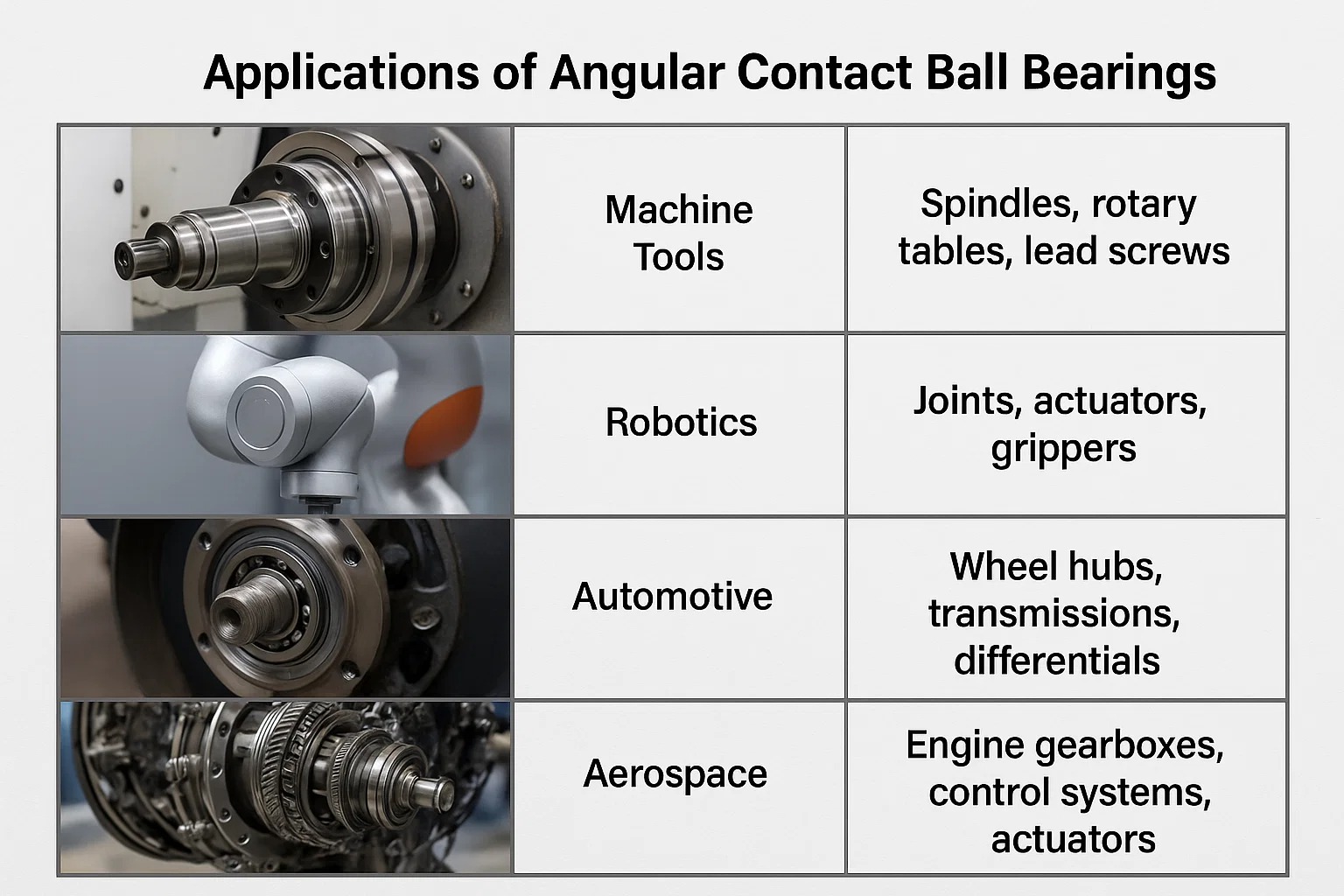

1. Machine Tools

Machine tools are perhaps one of the most critical environments for angular contact ball bearings, demanding the highest levels of precision and rigidity.

- Spindle support: This is a prime application. The spindle of a machine tool is the heart of its operation, where the cutting tool or workpiece rotates. These spindles require bearings that can withstand extremely high rotational speeds, heavy cutting forces (both radial and axial), and maintain micron-level precision to ensure the accuracy of the machined part. Angular contact ball bearings, often arranged in highly stiff matched sets (e.g., three or four bearings in a tandem/duplex configuration), provide the necessary stiffness, minimal runout, and damping characteristics crucial for precision grinding, milling, and turning operations.

- Precision machining: The direct impact of these bearings on the final product's quality cannot be overstated. Their ability to minimize runout (deviation from true rotation) and deflection directly translates to higher quality machined parts with tighter tolerances, superior surface finishes, and reduced chatter, leading to significant improvements in manufacturing efficiency and product integrity.

2. Robotics

Robotics, particularly in advanced manufacturing and automation, relies heavily on the precise and durable motion control offered by angular contact ball bearings.

- Joints and actuators: Robotic arms and manipulators utilize angular contact ball bearings in their joints and actuators to achieve precise, repeatable movements. These bearings support the complex combined loads (axial, radial, and moments) generated during dynamic operation, contributing significantly to the overall stiffness, accuracy, and smooth motion of the robotic system.

- High-precision movement: In applications like surgical robots, industrial assembly robots, or inspection systems, the smooth, backlash-free, and accurate motion facilitated by these bearings is paramount for successful and reliable operation. They ensure that robotic movements are exact, which is vital for delicate or highly repetitive tasks.

3. Automotive

The automotive industry uses angular contact ball bearings in numerous key components where reliability and load-carrying capacity are essential.

- Wheel bearings: Many modern automotive wheel bearings are integrated angular contact ball bearing units. These units are engineered to handle the significant radial loads from the vehicle's weight, as well as the substantial axial loads generated during cornering, braking, and acceleration. They are designed for long life and minimal maintenance.

- Transmission components: In some automotive transmissions and differentials, angular contact bearings are used to support shafts that experience both radial loads from gears and thrust loads from helical or bevel gears. Their ability to manage combined forces ensures efficient power transfer and smooth operation of the drivetrain.

4. Aerospace

The aerospace industry places extremely high demands on component reliability, weight efficiency, and performance under harsh conditions, making angular contact ball bearings a frequent choice.

- Engine applications: In aircraft engines, angular contact ball bearings are employed in various sections, including gearbox components, accessory drives, and even main shafts. Here, they must withstand extreme temperatures, very high rotational speeds, and demanding load conditions, often with precise balance requirements.

- Control systems: They are also found in critical aircraft control surfaces, landing gear mechanisms, and other actuation systems where reliability, precision, and low friction are non-negotiable for safe and effective flight operations.

Here's a summary table of the applications:

| Industry | Primary Application Areas | Key Benefits Provided by Bearings |

|---|---|---|

| Machine Tools | Spindles, rotary tables, lead screws | High precision, high rigidity, low runout, superior surface finish on parts |

| Robotics | Joints, actuators, grippers | Precise movement, high repeatability, compact design, combined load support |

| Automotive | Wheel hubs, transmissions, differentials | High reliability, combined radial & axial load capacity, long service life |

| Aerospace | Engine gearboxes, control systems, actuators | High speed capability, extreme temperature tolerance, critical reliability |

V. Materials and Manufacturing

The performance, durability, and lifespan of angular contact ball bearings are profoundly influenced by the materials from which they are made and the precision with which they are manufactured. These factors dictate the bearing's ability to withstand loads, speeds, and environmental conditions.

1. Bearing Materials

The choice of material for the bearing rings and balls is critical for determining its strength, wear resistance, and fatigue life.

-

Steel types (e.g., chrome steel, stainless steel):

- Chrome Steel (AISI 52100 / 100Cr6): This is the most common and widely used material for bearing rings and balls in standard industrial applications. It's a high-carbon chromium steel known for its excellent hardness, superior wear resistance, and high fatigue life. Its consistent performance and cost-effectiveness make it a go-to choice for a vast majority of bearing applications.

- Stainless Steel (e.g., AISI 440C): Used primarily in applications where corrosion resistance is paramount, such as in the food processing industry, medical equipment, marine environments, or in settings exposed to harsh chemicals. While offering good resistance to rust and staining, its load capacity and fatigue life are generally lower than that of chrome steel under similar conditions.

-

Ceramic options:

- Silicon Nitride (Si3N4) Ceramic Balls: These are increasingly specified for high-performance angular contact ball bearings, particularly in high-speed applications. Ceramic balls offer several significant advantages over steel:

- Lighter Weight: They are significantly lighter than steel balls, which drastically reduces centrifugal forces at high speeds. This leads to less friction, lower heat generation, and a longer effective grease life.

- Higher Stiffness & Hardness: Ceramic balls are much stiffer and harder than steel, contributing to increased bearing rigidity and enhanced wear resistance.

- Non-Magnetic & Electrically Insulating: They are non-magnetic and can act as an electrical insulator, making them ideal for applications where stray electrical currents could damage the bearing.

- Bearings with ceramic balls are often referred to as "hybrid bearings" because they combine ceramic rolling elements with steel rings.

- Silicon Nitride (Si3N4) Ceramic Balls: These are increasingly specified for high-performance angular contact ball bearings, particularly in high-speed applications. Ceramic balls offer several significant advantages over steel:

2. Cage Materials

The cage (or retainer) is a crucial component that keeps the rolling elements (balls) separated and equally spaced around the raceways. Its material impacts the bearing's speed capability, noise levels, lubrication effectiveness, and overall lifespan.

- Steel cages:

- Stamped Steel Cages: These are common for general-purpose bearings. They are robust, durable, and suitable for moderate speeds and temperatures. Their cost-effectiveness makes them a popular choice for a wide range of applications.

- Machined Steel Cages: Offer higher strength and are used in more demanding applications, especially where high loads or vibrations are present.

- Brass cages:

- Machined Brass Cages: These are often preferred for higher speeds and temperatures due to their excellent strength, superior lubricity (which reduces friction), and ability to withstand vibrations. They are also less susceptible to damage from certain types of contamination.

- Polymer cages (e.g., polyamide, PEEK):

- These lightweight cages are excellent for very high-speed applications because of their low friction, reduced noise, and ability to operate with minimal lubrication. However, they have specific temperature limitations and may not be suitable for extremely high-temperature environments. PEEK (Polyether Ether Ketone) offers higher temperature resistance than standard polyamide.

Here's a breakdown of common cage materials:

| Cage Material Type | Characteristics | Typical Applications |

|---|---|---|

| Stamped Steel | Robust, cost-effective, good for general applications, moderate speeds & temperatures. | General industrial machinery, automotive. |

| Machined Brass | High strength, good lubricity, vibration resistance, suitable for higher speeds & temperatures. | Machine tool spindles, pumps, high-performance industrial equipment. |

| Polyamide (Nylon) | Lightweight, low friction, quieter operation, good for very high speeds, lower temperature limits. | Electric motors, small machinery, high-speed applications where heat is managed. |

| PEEK | Lightweight, excellent for very high speeds and higher temperatures than polyamide, chemical resistance. | Aerospace, specialized high-speed machinery, medical equipment, demanding industrial uses. |

3. Manufacturing Processes

The precision and overall quality of angular contact ball bearings are the direct result of highly advanced and meticulously controlled manufacturing processes.

-

Precision grinding and finishing: Both the raceways (the grooves in the inner and outer rings) and the balls undergo multiple stages of precision grinding and superfinishing. This multi-step process ensures extremely smooth surfaces, exceptionally tight dimensional tolerances, and optimal geometrical accuracy. These factors are critical for achieving high precision, minimizing friction and heat generation, reducing noise and vibration, and ultimately, extending the bearing's service life. Any imperfections at this stage can lead to premature failure.

-

Quality control: Throughout the entire manufacturing process, from raw material inspection to the final product, rigorous quality control checks are implemented. This includes:

- Dimensional inspection: Ensuring precise measurements of all components.

- Surface finish analysis: Verifying the smoothness of raceways and balls.

- Hardness testing: Confirming the material's resistance to deformation and wear.

- Noise and vibration testing: Bearings are often tested for unacceptable noise levels or vibration patterns that could indicate internal defects.

- Each bearing is meticulously inspected and often undergoes a final performance check to ensure it meets stringent performance standards and reliability requirements before it leaves the factory.

VI. Installation and Maintenance

Proper installation and ongoing maintenance are absolutely crucial for maximizing the lifespan, reliability, and performance of angular contact ball bearings. Even the highest quality bearing can fail prematurely if not handled, installed, or maintained correctly.

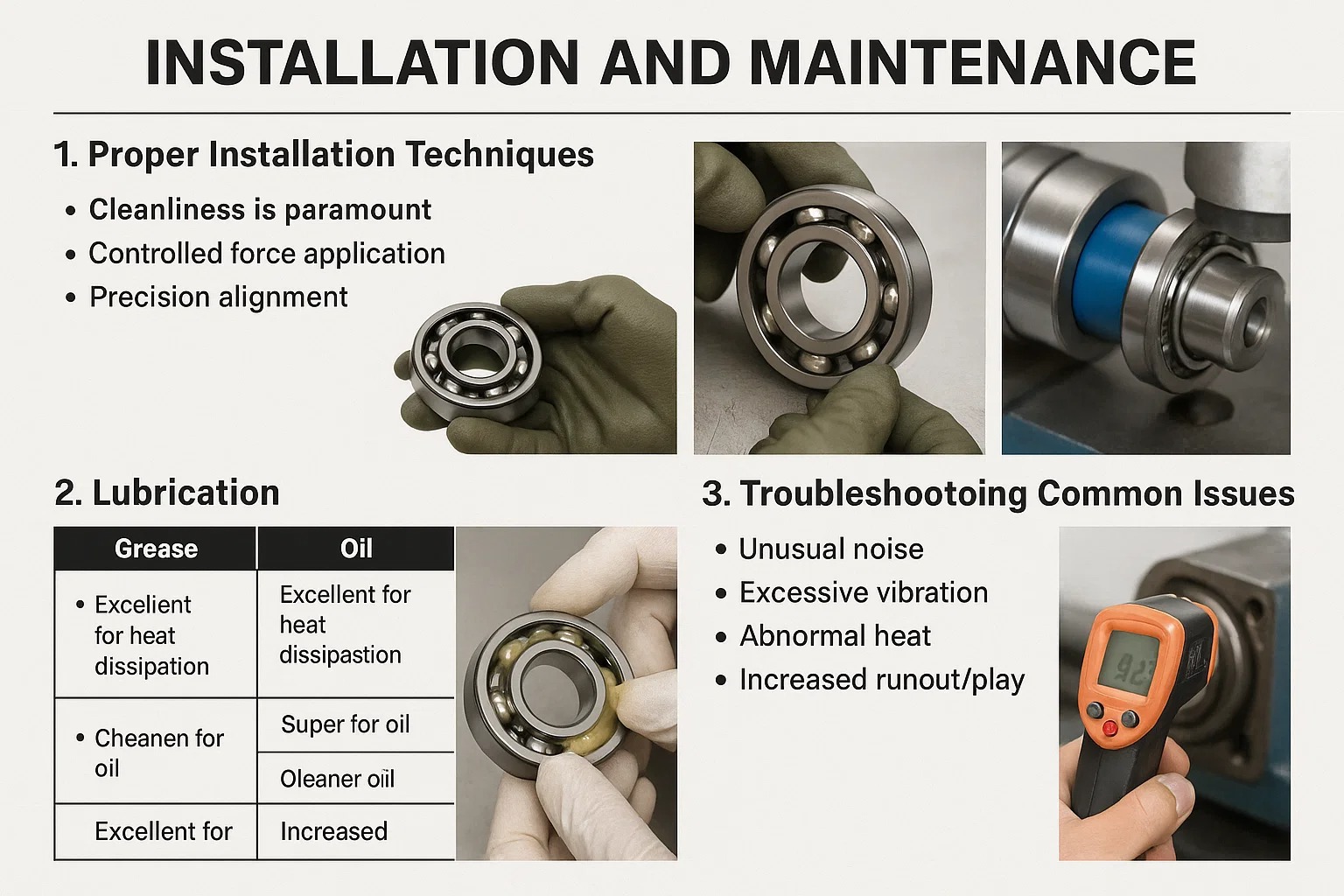

1. Proper Installation Techniques

Incorrect installation is, unfortunately, one of the leading causes of premature bearing failure. Taking the time to follow best practices can prevent significant downtime and costly repairs.

-

Handling and mounting:

- Cleanliness is paramount: Always handle bearings in a meticulously clean environment. Even tiny particles of dust, dirt, or metal shavings can act as abrasives, causing significant damage to the precision-ground surfaces of the raceways and balls, leading to premature wear and failure.

- Controlled Force Application: Never apply force directly to the outer ring when attempting to mount a bearing onto a shaft. Conversely, do not apply force to the inner ring when mounting the bearing into a housing. Using the wrong ring to apply force can brinell (dent) the raceways or deform the bearing components. Instead, use appropriate mounting tools such as bearing heaters (for thermal expansion), hydraulic presses, or specialized impact sleeves that ensure force is applied evenly and directly to the correct bearing ring (the one being press-fitted).

- Precision Alignment: Ensure that the bearing is perfectly aligned during the mounting process. Misalignment, even slight, can lead to uneven load distribution across the rolling elements, generating excessive heat, increasing friction, and causing premature localized wear that drastically shortens bearing life.

-

Avoiding damage: Avoid any hammering or excessive impact force during installation. Such actions can easily deform the bearing rings, raceways, or balls, leading to brinelling (permanent indentations), cracks, or other forms of damage that compromise the bearing's integrity and drastically shorten its lifespan. Always prioritize controlled, even force.

2. Lubrication

Lubrication is the lifeblood of a bearing. It's essential for reducing friction between rolling elements and raceways, preventing wear, dissipating heat generated during operation, and providing protection against corrosion.

- Grease vs. oil lubrication: The choice between grease and oil depends heavily on the specific operating conditions and application requirements.

| Lubricant Type | Characteristics | Ideal Applications | Considerations |

|---|---|---|---|

| Grease | • Simplistic application<br>• Clean operation<br>• Stays in place well | • Most common type for a wide range of speeds and temperatures<br>• Sealed bearings | • Limited heat dissipation<br>• Re-lubrication intervals are crucial |

| Oil | • Excellent for heat dissipation<br>• Superior at very high speeds<br>• Cleaner operation for high precision | • Very high-speed applications<br>• High-temperature environments<br>• Precision spindles | • Requires more complex sealing and delivery systems (e.g., oil-air, circulating) |

- Lubrication intervals: The frequency of re-lubrication (for grease) or oil change/ replenishment depends on numerous factors, including the bearing's operating speed, temperature, applied load, and the specific type of lubricant used. Always follow the bearing manufacturer's recommendations as a primary guide. It's also vital to remember that over-lubrication can be as detrimental as under-lubrication, potentially leading to excessive heat generation due to churning, increased friction, and even seal damage.

3. Troubleshooting Common Issues

Identifying the signs of bearing failure early can be the difference between a simple repair and catastrophic equipment breakdown, saving significant costs and downtime.

-

Identifying bearing failure: Common indicators that suggest a bearing problem include:

- Unusual Noise: Grinding, whining, squealing, rattling, or clicking sounds often point to lubrication issues, contamination, wear, or damage to the raceways or rolling elements.

- Excessive Vibration: An increase in vibration levels, detected through sensory inspection or vibration analysis equipment, is a strong indication of bearing damage, misalignment, or imbalance.

- Abnormal Heat: Excessive heat generation from the bearing housing usually suggests high internal friction, often due to insufficient lubrication, improper preload (too tight), or internal damage.

- Increased Runout/Play: Noticeable radial or axial play (movement) that wasn't present before indicates internal wear, loss of preload, or severe damage to the bearing's components.

-

Preventive maintenance: A robust preventive maintenance program is the key to significantly extending bearing life and preventing unexpected downtime. Key components include:

- Regular Inspections: Visual checks for signs of damage, leakage, or excessive dirt buildup.

- Vibration Analysis: Using specialized tools to monitor bearing health trends and detect early signs of deterioration.

- Temperature Monitoring: Regularly checking bearing housing temperatures to identify potential overheating issues.

- Scheduled Re-lubrication: Adhering strictly to manufacturer-recommended lubrication schedules and using the correct type and amount of lubricant.

VII. Selecting the Right Angular Contact Ball Bearing

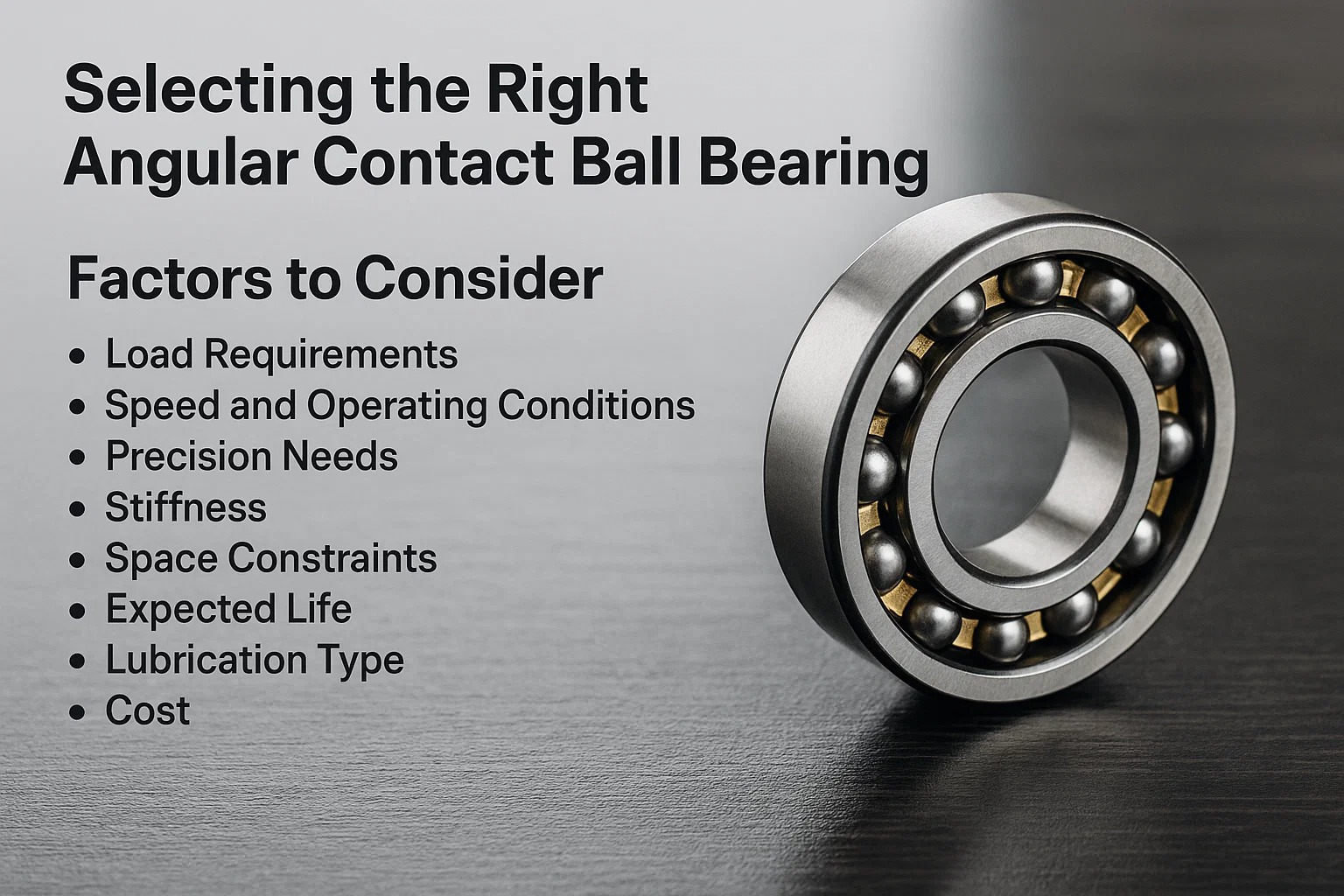

Choosing the correct angular contact ball bearing is a critical decision that directly impacts the performance, longevity, and cost-effectiveness of your machinery. A careful evaluation of several key factors is essential to ensure you select the bearing that perfectly matches your application's demands.

1. Factors to Consider

Selecting the ideal angular contact ball bearing involves a systematic assessment of the operating conditions and performance requirements. Overlooking any of these factors could lead to premature failure or suboptimal performance.

| Factor | Description |

|---|---|

| Load Requirements | This is paramount. You need to accurately determine both the magnitude and direction of radial loads and axial loads. Is the axial load unidirectional or bidirectional? Are there significant shock loads or vibrations? The specific load combination will directly influence the required contact angle and whether a single bearing or a duplex arrangement (e.g., DF, DB, DT) is necessary. |

| Speed and Operating Conditions | Assess the maximum operating speed and the desired speed factor (ndm). High speeds often necessitate smaller contact angles, specialized cage materials (like PEEK or polyamide), and specific lubrication methods (e.g., oil-air lubrication). Crucially, consider the operating temperature range and the ambient environment (e.g., presence of corrosive agents, dust, moisture, or extreme temperatures). |

| Precision Needs | Determine the required running accuracy and rigidity (stiffness) of your system. Applications like machine tool spindles demand extremely high precision, often requiring bearings of higher precision classes (e.g., P4, P2), matched sets, and carefully controlled preload to minimize runout and deflection. |

| Stiffness | How much deflection can the application tolerate under load? If high stiffness and minimal shaft movement are critical, then duplex arrangements (especially Back-to-Back or DB configuration) will be necessary to provide robust support against bending moments and axial shifts. |

| Space Constraints | The available axial and radial space within the housing and on the shaft will dictate the permissible bearing dimensions (bore, outer diameter, width). This can influence whether a compact single-row, a double-row, or a four-point contact bearing is the most suitable choice. |

| Expected Life | Calculate the desired bearing service life, typically expressed in hours or millions of revolutions. This calculation, based on the dynamic load rating (C), static load rating (C0), and equivalent dynamic load (P), will guide the selection of the appropriate bearing size and type to meet reliability targets. |

| Lubrication Type | Based on speed, temperature, and maintenance intervals, decide whether grease lubrication or oil lubrication is more appropriate. High speeds often demand oil for better heat dissipation, while grease offers simpler application and containment for many standard uses. |

| Cost | Balance the required performance specifications with budget constraints. Higher precision classes, specialized materials (like ceramics), and complex duplex arrangements typically come at a higher cost. An optimal selection balances performance with economic viability. |

2. Bearing Numbering System

Understanding the manufacturer's numbering or designation system is absolutely essential for accurate bearing identification, replacement, and selection. It's the "language" used to describe a bearing's specific characteristics.

-

Understanding bearing designations: Each bearing type and variant is assigned a specific designation (part number) by the manufacturer. This alphanumeric code is not arbitrary; it encodes vital information about the bearing. Typically, it includes details about:

- Basic dimensions: Such as bore diameter, outer diameter, and width.

- Bearing series: Indicating the dimension series and sometimes the load capacity relative to its bore.

- Internal design: Specifying the contact angle (e.g., A, C, E), cage material (e.g., M, T, F), and internal clearance or preload.

- Precision class: Indicating the manufacturing accuracy (e.g., P6, P5, P4, P2, with P2 being the highest precision).

- Special features: Such as seals, shields, or specific lubrication.

-

Interpreting manufacturer catalogs: Bearing manufacturers provide comprehensive catalogs, both in print and online, that serve as invaluable resources. These catalogs detail their specific numbering systems and provide extensive technical specifications for each bearing designation. You'll find information on:

- Dynamic load rating (C): The constant radial load that a bearing can endure for a specified rating life (typically 1 million revolutions)

- Static load rating (C0): The static radial load that corresponds to a total permanent deformation of rolling element and raceway at the most heavily stressed contact point.

- Limiting speeds: Maximum permissible operating speeds with different lubrication methods.

- Dimensions: Exact measurements of bore, outer diameter, and width.

- Recommended operating conditions: Guidelines for proper application. Familiarity with these catalogs is key to making informed and accurate selection decisions, ensuring the chosen bearing will perform as expected in the intended application.

Conclusion

This comprehensive guide has explored the intricate world of angular contact ball bearings, shedding light on their unique design, diverse applications, and significant advantages. We've delved into what defines these bearings, why they are often the preferred choice over other types, and how their internal mechanics allow them to efficiently manage complex load combinations.

1. Recap of Key Points

Throughout this guide, we've covered the fundamental aspects that make angular contact ball bearings indispensable in modern machinery:

- Understanding the Design: We defined angular contact ball bearings by their ability to handle both radial and axial loads simultaneously, driven by their critical contact angle. We explored different configurations, including single-row, double-row, and four-point contact bearings, as well as the crucial role of duplex arrangements (DF, DB, DT) for enhanced rigidity and load capacity.

- Key Features & Benefits: We highlighted their outstanding capabilities in high load capacity, handling complex load combinations efficiently. Their inherent design allows for exceptional high-speed performance and contributes to remarkable precision and rigidity, minimizing runout and deflection in critical applications.

- Diverse Applications: We saw how these bearings are vital across numerous industries, from the precision required in machine tools and robotics to the demanding environments of automotive and aerospace components.

- Materials & Manufacturing Excellence: We examined the importance of material selection, including chrome steel and stainless steel, and the advantages of ceramic options for enhanced performance. We also touched upon the impact of various cage materials and the rigorous precision manufacturing processes that ensure quality and reliability.

- Installation & Maintenance Best Practices: Finally, we emphasized that even the best bearings require proper installation techniques and diligent lubrication to achieve their intended lifespan, and we provided insights into troubleshooting common issues to prevent premature failure.

2. The Future of Angular Contact Ball Bearings

The journey of angular contact ball bearings is far from over. As technology continues its relentless march forward, we anticipate several key developments that will further enhance their capabilities and expand their applications:

- Advanced Materials: Expect continued innovation in material science, leading to the development of even lighter, stronger, and more temperature-resistant steels and composites. Hybrid bearings with enhanced ceramic components will become more commonplace, pushing the boundaries of speed and efficiency while reducing friction and heat.

- Enhanced Precision & Performance: Manufacturing precision will undoubtedly reach new heights, enabling bearings with even tighter tolerances and improved surface finishes. This will allow for higher rotational speeds, greater load densities within more compact designs, and extended operational life.

- Smart Bearing Technology: The integration of "smart" features, such as embedded sensors for real-time monitoring of temperature, vibration, and lubrication status, will become increasingly prevalent. This technological leap will enable highly accurate predictive maintenance, allowing operators to anticipate and address potential issues before they lead to costly failures, thereby optimizing uptime and extending the service life of both the bearings and the machinery they support.

As industries continue to push the boundaries of speed, precision, and efficiency, angular contact ball bearings will remain a critical enabling technology, constantly evolving to meet the next generation of engineering challenges.

English

English 中文简体

中文简体 عربى

عربى

Download Catalog

Download Catalog