Shaoxing Shangyu Flight Seiko Machinery Co., Ltd. (FTM) is proud to present our specialized Type Track Rollers Bearing Without Inner Ring. Leveraging over 30 years of technical design expertise, we deliver high-quality, non-standard bearing solutions that meet the rigorous demands of modern industrial applications, including engineering machinery and textile machinery.

Key Product Features and Advantages

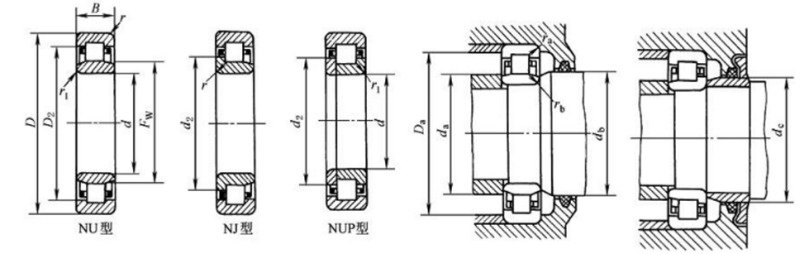

Track rollers without an inner ring are a distinct and highly advantageous type of rolling element bearing, typically utilizing a set of rollers or needles (often featuring a cage for guidance) and an outer ring.

- Exceptional Space Efficiency: The fundamental feature of this design is the absence of a dedicated inner ring, resulting in a remarkably low radial cross-section height. This is ideal for support structures with stringent radial installation space limitations, allowing for compact and weight-saving machine designs.

- High Load Capacity: Utilizing a full complement of rollers or a caged roller/needle assembly, these bearings are engineered to handle substantial static and dynamic loads. The extended contact length between the rolling elements and the raceway ensures superior bearing capacity, often making them comparable to deep groove ball bearings of similar size.

- Superior High-Speed Performance: By running directly on a hardened and ground shaft (which acts as the inner raceway), these bearings exhibit a lower coefficient of friction. This allows them to achieve limit speeds close to those of deep groove ball bearings, making them well-suited for high-speed rotation applications.

- Installation Flexibility & Simplified Maintenance: The separable design, where the outer ring assembly can be separated from the rollers/needles, offers significant installation and disassembly convenience. Maintenance and replacement become more straightforward, allowing customers the flexibility to use the hardened and polished equipment shaft as the inner raceway, or to optionally integrate an appropriate inner ring based on application requirements.

FTM Manufacturer's Edge

As a specialist in non-standard bearings and high-precision bearings (import substitution) since 2006, FTM offers distinct advantages:

- 30+ Years of Technical Acumen: We harness decades of technical design and manufacturing experience to ensure every bearing is produced to the highest standards of quality and precision.

- Customization and Specialization: Our core strength lies in the R&D, manufacturing, and customization of tailored bearing solutions. For track rollers without inner rings, this means we can engineer specific dimensions, materials, tolerances, and roller/cage configurations to perfectly match unique application loads, speeds, and environments.

- Commitment to Quality: We focus on delivering high-quality bearings that serve as reliable import substitutes, ensuring performance and durability that meets or exceeds international standards.

- Professional Technical Support: Our dedicated technical team is ready to provide high-quality bearing solutions and expert guidance to domestic and international customers across various industrial sectors.

Frequently Asked Questions (FAQ)

Q: What is the main advantage of this bearing type?

A: Extremely compact radial design (low cross-section) and high load capacity for space-restricted support structures.

Q: What shaft preparation is required?

A: The shaft must be hardened, precisely ground, and polished to serve effectively as the inner raceway.

Q: How does its load capacity compare?

A: It handles heavy radial loads with superior capacity relative to its cross-section, often comparable to deep groove ball bearings.

Q: Are these bearings suitable for high speeds?

A: Yes, the low friction allows for high-speed rotation, with limit speeds approaching deep groove ball bearings.

Q: Can FTM customize the design or materials?

A: Yes, absolutely. As a non-standard bearing specialist, FTM customizes dimensions, materials, tolerances, and sealing to meet specific application requirements.

English

English 中文简体

中文简体 عربى

عربى

Type track rollers bearing with inner rings are indispensable components that play a crucial role in facilitating smooth and reliable linear motion. With their robust construction, adaptability, and efficiency, these bearings stand as a testament to the advancements in bearing technology, meeting the diverse needs of industries where precision and reliability are paramount.

Type track rollers bearing with inner rings are indispensable components that play a crucial role in facilitating smooth and reliable linear motion. With their robust construction, adaptability, and efficiency, these bearings stand as a testament to the advancements in bearing technology, meeting the diverse needs of industries where precision and reliability are paramount.

Download Catalog

Download Catalog