Precision Bearings for Machine Tool Lead Screws: FTM’s High-Performance Solutions

FTM (Shaoxing Shangyu Flight Seiko Machinery Co., Ltd.), leveraging over 30 years of technical design expertise in high-quality bearing manufacturing, proudly presents our specialized range of Angular Contact Ball Bearings engineered explicitly for Machine Tool Lead Screws.

These bearings are meticulously designed to meet the rigorous demands of high-precision machining in sophisticated multi-axis machine centers, ensuring perfect alignment and highly reliable support for the lead screw drive system.

Key Features and Performance

Our Lead Screw Bearings are the foundation for achieving superior machining results:

- High Stability and Rigidity: Engineered with optimal contact angles to maximize axial and radial stiffness, effectively suppressing vibration and deflection during high-load and intermittent cutting operations.

- High Speed Capability: Optimized cage design and precision-matched components allow for exceptionally high rotational speeds, crucial for enhancing machine tool throughput and rapid traverse rates.

- Ultra-High Precision: We guarantee dimensional accuracy up to P4 (ABEC 7) and rotational accuracy up to P2 (ABEC 9), ensuring minimal runout and maximizing the positioning accuracy of the lead screw.

- High Carrying Capacity: Designed to manage high axial thrust loads inherent in lead screw applications, guaranteeing extended performance life under demanding operating conditions.

- Long Service Life: The combination of superior material selection, advanced heat treatment, and precision grinding significantly extends the Mean Time Between Failures (MTBF) and reduces maintenance downtime.

FTM Manufacturer Advantage

Choosing FTM means partnering with a specialist in import substitution and non-standard precision:

- 30+ Years of Technical Heritage: Our experience allows us to move beyond standard catalogue offerings, providing deep technical insights and proven solutions for the most challenging applications.

- Import Substitution Capability (High-Precision Bearings): We specialize in matching and surpassing the performance metrics of globally renowned high-precision bearing brands, offering a local, reliable, and cost-effective source for critical components.

- Customization (Non-Standard Bearings): Unlike general manufacturers, FTM excels at the R&D and customization of bearings and mechanical parts, tailoring features like contact angle, pre-load, and sealing arrangements to the exact specifications of your machine design.

- Quality Assurance: Commitment to extreme tolerance control (up to P2) ensures that our bearings are perfectly suited for applications like CNC machine tools where micron-level accuracy is non-negotiable.

Typical Applications

Due to their superior performance envelope, FTM Lead Screw Bearings are essential components across a wide range of high-performance machinery:

- Industrial Machinery: CNC Machine Tools (Lathes, Mills, Grinders), Machining Centers, Injection Molding Machines.

- High-Tech Manufacturing: Laser Cutting Machines, Plasma Cutting Systems, Coordinate Measuring Machines (CMM).

- Medical and Transportation: Advanced Medical Imaging Equipment, High-Speed Rail Bogies, Precision Actuation Systems in Aircraft/Aerospace.

Frequently Asked Questions (FAQ)

1. What is the significance of the P2/P4 tolerance grades for lead screw bearings?

Answer: P4 (ABEC 7) is a very high standard for dimensional accuracy (width, bore, outside diameter), while P2 (ABEC 9) is the highest standard for rotational accuracy (radial and axial runout). For a lead screw, this extreme precision minimizes wobble and positional error, which is crucial because any microscopic movement in the bearing translates directly into a loss of accuracy on the workpiece. FTM’s ability to manufacture to these tight tolerances ensures your machine achieves its full precision potential.

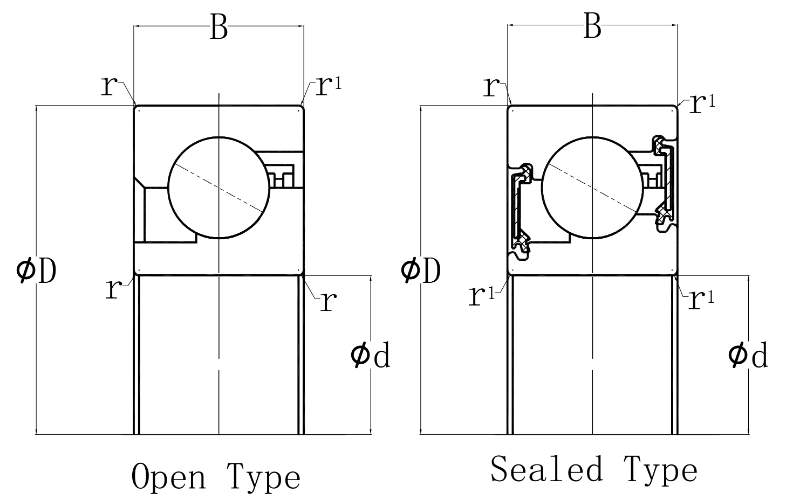

2. How does the angular contact design benefit lead screw applications?

Answer: Angular contact ball bearings are specifically designed to handle combined radial and significant axial (thrust) loads simultaneously. In lead screw applications, the screw drive generates high axial forces (thrust) during movement and machining. The contact angle in these bearings allows the internal geometry to effectively manage and sustain these high thrust loads while maintaining precise radial support, leading to higher rigidity and longer life.

3. Should I choose a single bearing or a pre-loaded matched set?

Answer: For high-precision applications like multi-axis machining centers, you should always opt for pre-loaded matched sets. FTM supplies these bearings in duplex, triplex, or quadruplex arrangements (e.g., DF/DB/DT/DQ). The bearings are individually ground and permanently marked to ensure a precise, predetermined level of internal pre-load when mounted. This pre-load eliminates internal clearance, dramatically increases rigidity, and minimizes axial displacement, which is vital for maintaining tool positioning accuracy.

4. What material is typically used for the bearing cage to support high speeds?

Answer: For extremely high-speed applications, standard steel cages may limit performance. FTM utilizes specialized materials, often phenolic resin (or occasionally polymer/textile composites), for the retainer (cage). These materials are lighter, offer better low-friction running characteristics, and have high-speed stability, making them ideal for the demands of rapid traverse and high-RPM machining.

5. Can FTM assist with determining the correct pre-load and mounting configuration?

Answer: Yes. FTM’s advantage is our 30+ years of technical design experience. Our technical team works closely with your engineers to analyze the required stiffness, load profile, and speed parameters of your machine. We then recommend the optimal bearing arrangement (e.g., DF, DB, DT), the specific pre-load class (light, medium, heavy), and provide guidance on correct installation to ensure the full intended rigidity and lifespan are achieved.

English

English 中文简体

中文简体 عربى

عربى

Download Catalog

Download Catalog