As a leading specialist in non-standard and high-precision bearing solutions, Shaoxing Shangyu Flight Seiko Machinery Co., Ltd. (FTM) leverages over 30 years of technical design experience to deliver superior components. Our Custom Pulley Bearing Rings are a prime example of our commitment to import substitution-grade quality and tailored manufacturing excellence.

Product Overview

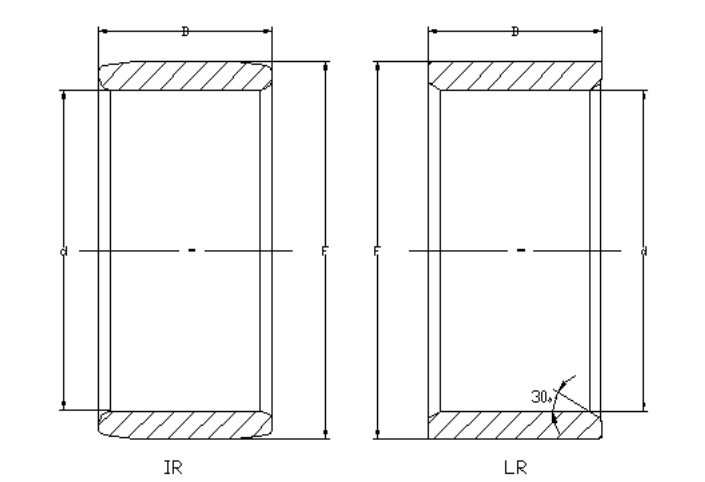

A Pulley Bearing Ring is a foundational structural component integrated into the inner or outer raceway assembly of a pulley bearing. Its primary and critical role is to support and precisely fix the rolling elements, ensuring the bearing operates with optimal stability, reduced friction, and extended service life. FTM specializes in the customization of these rings in a wide range of sizes, guaranteeing a perfect fit for diverse customer applications.

Key Functions and Engineering Excellence

Our custom pulley bearing rings are engineered to deliver measurable performance benefits:

- Superior Support and Alignment: The rings provide critical support, maintaining the smooth trajectory of the rolling elements and ensuring precise coaxial alignment between the inner and outer bearing rings. This foundational stability is essential for high-speed and dynamic operations.

- Friction and Heat Reduction: By machining the rings to high-precision grades (P2, P4), FTM ensures a highly complementary fit with the rolling elements and raceways. This precise matching minimizes running friction, which in turn reduces operational heat and allows the pulley bearing to maintain smooth, reliable performance even under high speed and heavy load conditions.

- Enhanced Load Capacity and Durability: FTM selects appropriate, high-quality materials such as bearing steel (e.g., GCr15), 45# steel, and other specialized alloys based on the application's demands. Through meticulous structural design and material choice, we significantly improve the bearing's overall static and dynamic load-carrying capacity, making our rings ideal for heavy-duty environments like engineering and textile machinery.

- Robust Protection: The ring structure contributes to the bearing's overall sealing capability, helping to prevent ingress of contaminants (dust, moisture, foreign particles) into the critical raceway and rolling element area. This defense against wear-inducing impurities significantly extends the operational lifespan and reduces maintenance frequency.

FTM Manufacturing Advantage

Our ability to provide high-quality bearing solutions stems from our core strengths:

- Customization Focus: We specialize in non-standard customization, offering flexible design and production to meet unique specifications, dimensions, and material requirements that off-the-shelf components cannot satisfy.

- High-Precision Manufacturing: FTM ensures superior component performance by adhering to ultra-high precision standards (down to P4/ABEC 7), guaranteeing exceptional concentricity, roundness, and surface finish.

- Extensive Processing Range: We handle a broad spectrum of production needs, with a size processing range spanning from a diameter of 10mm up to 250mm.

- Material Expertise: Our in-house technical team provides material selection consultancy to match the operating environment (temperature, load, corrosion risk) with the optimal material (e.g., GCr15 for standard high-stress, or specialized stainless steels).

Custom Pulley Bearing Rings: Frequently Asked Questions (FAQ)

Q: What is the main difference between FTM's P4 precision rings and standard rings?

A: P4 (ABEC 7) rings feature tighter dimensional tolerances, better geometry, and smoother finishes. This results in lower friction, less vibration, and a longer service life compared to standard P0/P6 rings.

Q: What non-standard features can FTM customize besides size and material?

A: We customize raceway profile geometry (e.g., V/U-groove), internal/external features (e.g., mounting holes), heat treatment specifications, and specialized surface coatings.

Q: Which core industries most benefit from high-precision pulley bearing rings?

A: Industries requiring high reliability and speed, particularly textile machinery, high-speed automation equipment, and heavy-duty engineering machinery.

Q: What is the typical lead time for a customized batch?

A: Lead time generally ranges from 4 to 8 weeks after final design confirmation. This varies based on complexity, material, precision grade, and order volume.

Q: What is the target surface hardness for your GCr15 bearing steel rings?

A: Following heat treatment, we target a high surface hardness of 60-64 HRC (Rockwell Hardness C scale) to ensure maximum wear resistance.

English

English 中文简体

中文简体 عربى

عربى

Download Catalog

Download Catalog