I. Introduction: The New Reality of Sourcing from China If you have been in the mechanical industry for a while, you know the old stereotype: “Sourcing from China is great for the budget, but risky fo...

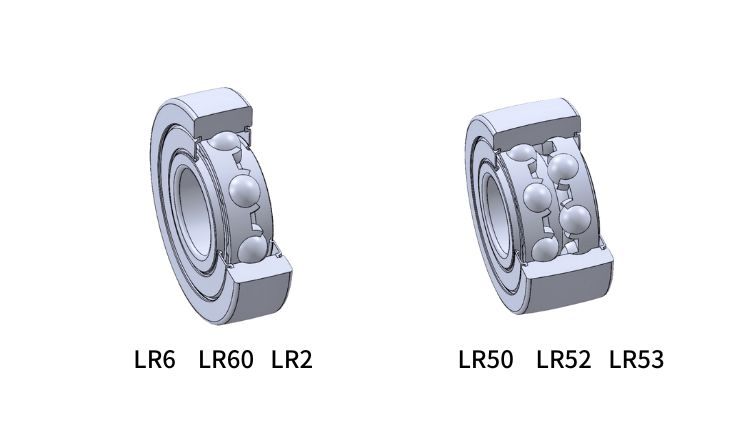

FTM's single row ball roller roller bearings are specially designed bearings to support radial and axial loads while minimizing friction on the rotating parts. These bearings are unique because of their spherical rolling elements that distribute load, ensuring smoother operation and increased efficiency.

Single row ball roller roller bearing is a precision engineering machinery component, FTM can provide P2,P4 precision production, and can be customized to match the application of the industry (automotive, aerospace, mechanical and robotics)

English

English 中文简体

中文简体 عربى

عربى

Download Catalog

Download Catalog