Shaoxing Shangyu Flight Seiko Machinery Co., Ltd. (FTM) leverages over 30 years of technical design experience to deliver high-performance bearing solutions. The FTM RU Series Crossed Roller Bearing is a testament to this expertise, engineered for applications that demand exceptional precision, high rigidity, and superior load capacity in a compact, easy-to-install package.

Product Overview and Key Features

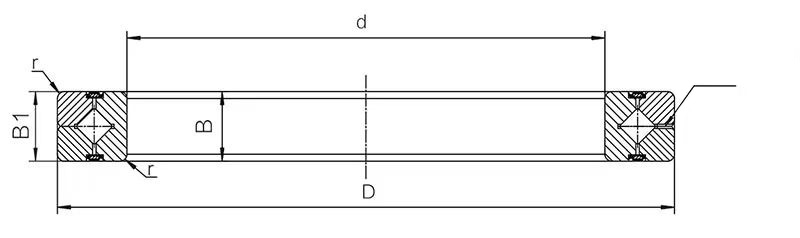

The RU Series is a unique configuration within the crossed roller bearing family, setting it apart with its distinctive design:

- Integrated Structure for Direct Mounting: Unlike standard crossed roller bearings that require separate housings or fixing flanges, the RU series features integrated inner and outer rings with pre-drilled mounting holes. This design simplifies the surrounding structure, significantly reducing the total system cost, installation time, and assembly complexity.

- High Precision and Stability: The RU Series utilizes cylindrical rollers arranged orthogonally (crossed) at a 90-degree V-groove. This geometry ensures that a single bearing can handle loads in all directions—radial, axial, and moment—with stable rotational accuracy and high running precision, making it ideal for precision rotary tables and robotic joints.

- Exceptional Rigidity and Load Capacity: The line contact between the rollers and raceways, combined with the large number of rollers within the compact space, provides superior rigidity and high-load capacity. This ensures reliable and dependable performance even in demanding conditions with intermittent heavy loads or high-speed indexing.

Advanced Customization and Materials (FTM Advantage)

As a specialized manufacturer focusing on non-standard and high-precision bearings (import substitution), FTM offers significant advantages in material selection and customization:

- Premium Material Options: Typically manufactured from high-strength, hardened bearing steel (such as high-carbon chromium bearing steel), FTM also offers options like hardened stainless steel for environments requiring enhanced corrosion resistance.

- Extended Service Life Customization: To protect the bearing in harsh or contaminated industrial environments, FTM can integrate specialized seals into the custom crossed roller bearings, preventing ingress of dust and debris and retaining lubrication to extend service life and reduce maintenance downtime.

- 30+ Years of Technical Design Experience: Our deep technical expertise allows us to provide high-quality bearing solutions that meet precise customer specifications, offering a reliable, high-precision alternative to imported components across various fields, including engineering machinery and textile machinery.

Extended Knowledge: Applications and Alternatives

Typical Applications

The exceptional characteristics of the RU Series make it the preferred choice for several high-tech and industrial applications:

- High-Precision Rotary Tables (e.g., in CNC machinery)

- Industrial Robotics (especially articulated joints and harmonic drives)

- Medical Diagnostic Equipment

- Measuring and Inspection Instruments

- Precision Indexing Mechanisms

RU Series vs. Standard Crossed Roller Bearings (RB/RE/CRB)

The key differentiator is the ring structure:

| Series |

Inner Ring |

Outer Ring |

Mounting |

| RU Series |

Integrated (one piece) |

Integrated (one piece) |

Direct Bolt-Down (most compact) |

| RB/RE Series |

Split (two halves) |

Integrated (one piece) |

Typically requires a separate housing |

FAQ for FTM RU Crossed Roller Bearings

1. What is the main advantage of the RU Series' integrated design?

The main advantage is simplification of the surrounding machine structure. The integrated inner/outer rings with mounting holes eliminate the need for separate housing, clamping plates, or fixing flanges, leading to a more compact design and faster, more accurate installation.

2. Can FTM provide the RU Series with special corrosion protection?

Yes. FTM specializes in customization. If the application environment is harsh or humid, we can manufacture the RU Crossed Roller Bearing using hardened stainless steel or apply specific surface treatments to enhance corrosion resistance.

3. How does the RU bearing handle moment loads?

The crossed roller arrangement is intrinsically excellent at handling high overturning moment loads (moment loads). The line contact and 90-degree V-groove configuration ensure uniform load distribution, providing superior stiffness and precision under eccentric loading.

4. What information do I need to provide for a custom non-standard RU bearing quotation?

To accurately quote a custom non-standard RU bearing, we require the following key information: Required bore/outer diameter, required load capacity (radial/axial/moment), required rotational accuracy, operating environment (temp/contamination), and required service life.

5. How do I ensure correct mounting and achieve the stated precision?

To achieve optimal performance, the mounting surface must be precisely machined (flatness and perpendicularity) to match the bearing's inherent precision. Due to the high-precision nature, FTM recommends following the specified torque requirements for the mounting bolts to avoid ring deformation.

Ready to enhance the precision and performance of your machinery? Contact FTM today to discuss how our custom-engineered RU Series Crossed Roller Bearings can provide the ideal solution for your demanding application.

English

English 中文简体

中文简体 عربى

عربى

Download Catalog

Download Catalog