At Shaoxing Shangyu Flight Seiko Machinery (FTM), we leverage over 30 years of technical design expertise to deliver high-performance motion solutions. The RA Series Crossed Roller Bearing represents the pinnacle of compact engineering, designed specifically for applications where space is at a premium but performance cannot be compromised.

Engineering Excellence and Design

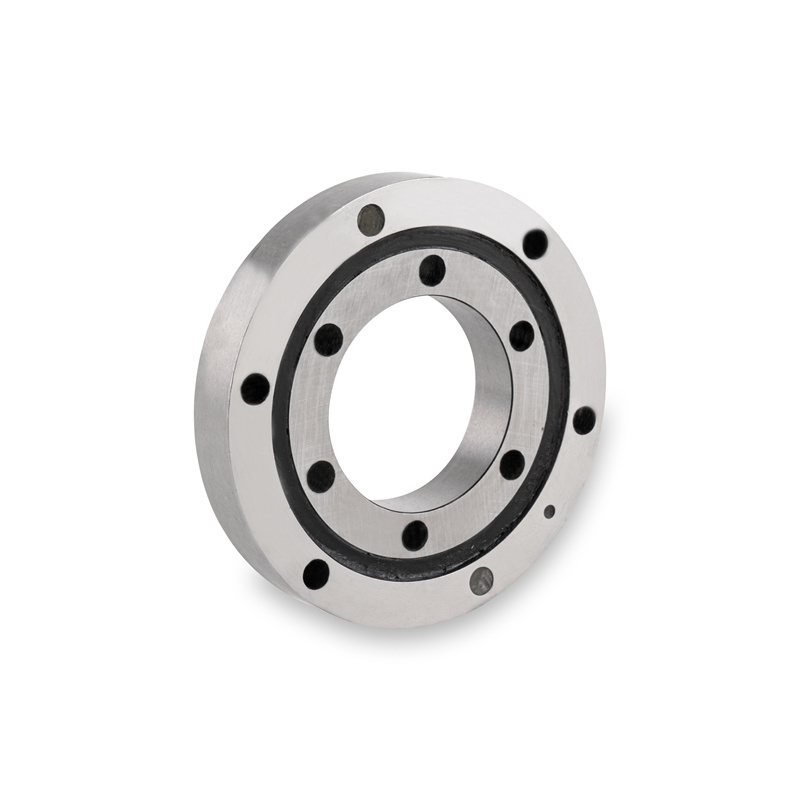

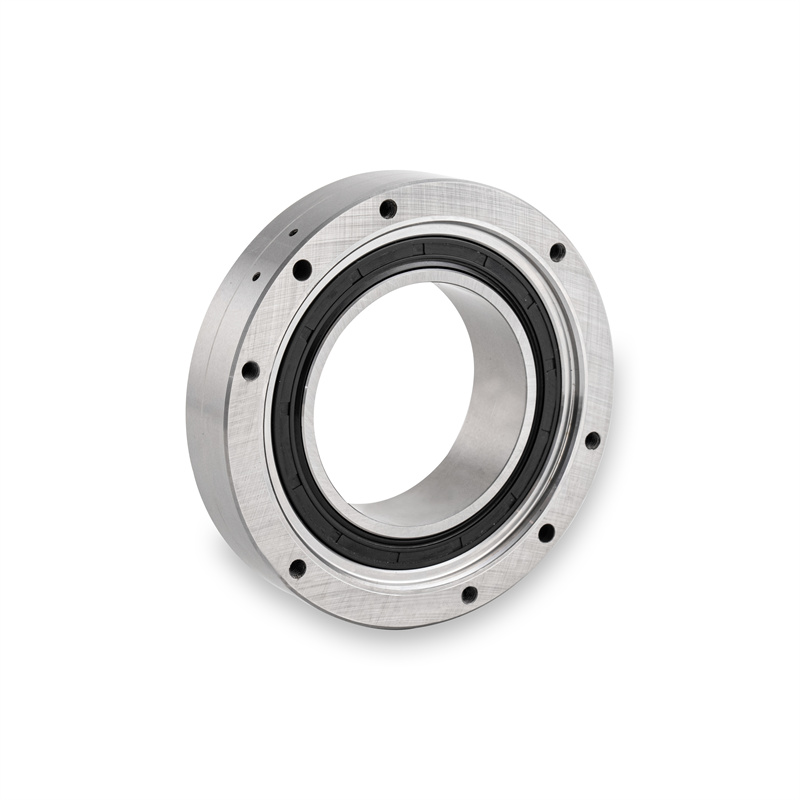

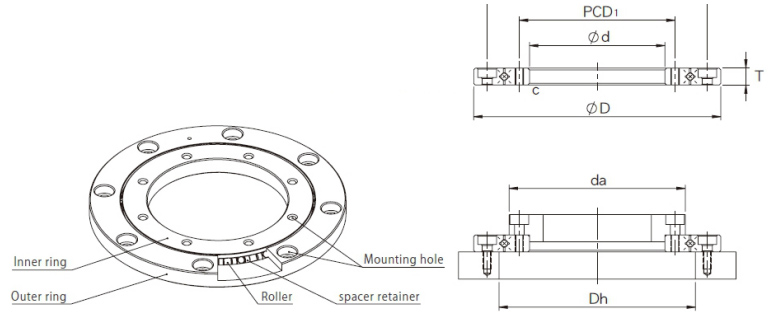

The RA Series features a sophisticated design where cylindrical rollers are arranged orthogonally (crossed) at 90 degree angles in a V-shaped groove. This unique geometry allows a single bearing to handle complex load combinations including radial, axial, and tilting moment loads simultaneously.

By integrating a one-piece inner and outer ring structure, the RA Series achieves a significantly thinner wall thickness than traditional bearings. This ultra-slim cross-section makes it an ideal choice for the next generation of lightweight, high-precision equipment. Whether your application requires inner or outer ring rotation, the RA Series provides the smooth, consistent torque necessary for delicate operations.

Key Performance Characteristics

- Superior Precision: Available in P4 and P2 high-precision grades, ensuring minimal runout for critical positioning tasks.

- Enhanced Rigidity: Factory-set preloading eliminates internal clearance, providing high mechanical stiffness and vibration resistance.

- Optimized Space Efficiency: Its remarkably small footprint allows engineers to reduce the overall size and weight of machine tools and robotic housings.

- High Load Capacity: Despite its slender profile, the crossed-roller design offers a much higher contact area than ball bearings, allowing for heavy load-bearing capabilities.

Typical Applications

Given its blend of lightweight design and high accuracy, the RA Series is the preferred solution for:

- Industrial robotic joints and robotic arms.

- High-precision rotary tables and indexing heads.

- Medical diagnostic equipment and imaging scanners.

- Textile machinery and semiconductor manufacturing equipment.

The FTM Advantage

As a specialist in non-standard and high-precision import substitution, FTM provides more than just a component. We provide a partnership. Our technical team works directly with your engineers to customize RA Series bearings to your specific environmental requirements, ensuring that every part delivers the durability and smooth rotation your brand depends on.

Frequently Asked Questions (FAQ)

1. What makes the RA Series different from the RB or RE Series?

The RA Series is the slim-type version of the crossed roller bearing family. While it shares the same internal structure as the RB series, it features a much thinner cross-section, making it significantly lighter and more space-efficient for compact devices.

2. Can FTM customize RA Series bearings for specific environments?

Yes. Our R&D team can provide customizations regarding materials, surface treatments, and specialized lubrication to suit extreme temperatures, cleanroom environments, or vacuum conditions common in robotic applications.

3. How does the crossed roller design improve accuracy over standard ball bearings?

Because the rollers have a linear contact area rather than a point contact, they experience less elastic deformation under load. This results in higher rigidity and eliminates the clearance issues that can cause inaccuracy in high-speed or high-precision rotations.

4. Is the RA Series suitable for both inner and outer ring rotation?

Absolutely. The integrated design of the RA Series ensures that the bearing maintains its high accuracy and smooth rotation regardless of whether the inner ring or the outer ring is the rotating component.

5. What is the lead time for RA Series bearings at FTM?

While lead times vary based on specific precision requirements (P4 vs P2) and customization needs, our established manufacturing processes in Shaoxing allow us to offer competitive delivery schedules for both domestic and international shipping.

English

English 中文简体

中文简体 عربى

عربى

Download Catalog

Download Catalog