At Shaoxing Shangyu Flight Seiko Machinery (FTM), we leverage over 30 years of technical expertise to deliver high-performance harmonic reducer bearings designed for the most demanding industrial applications. As automation and robotics continue to evolve, the need for components that combine compact design with extreme rotational accuracy has never been greater.

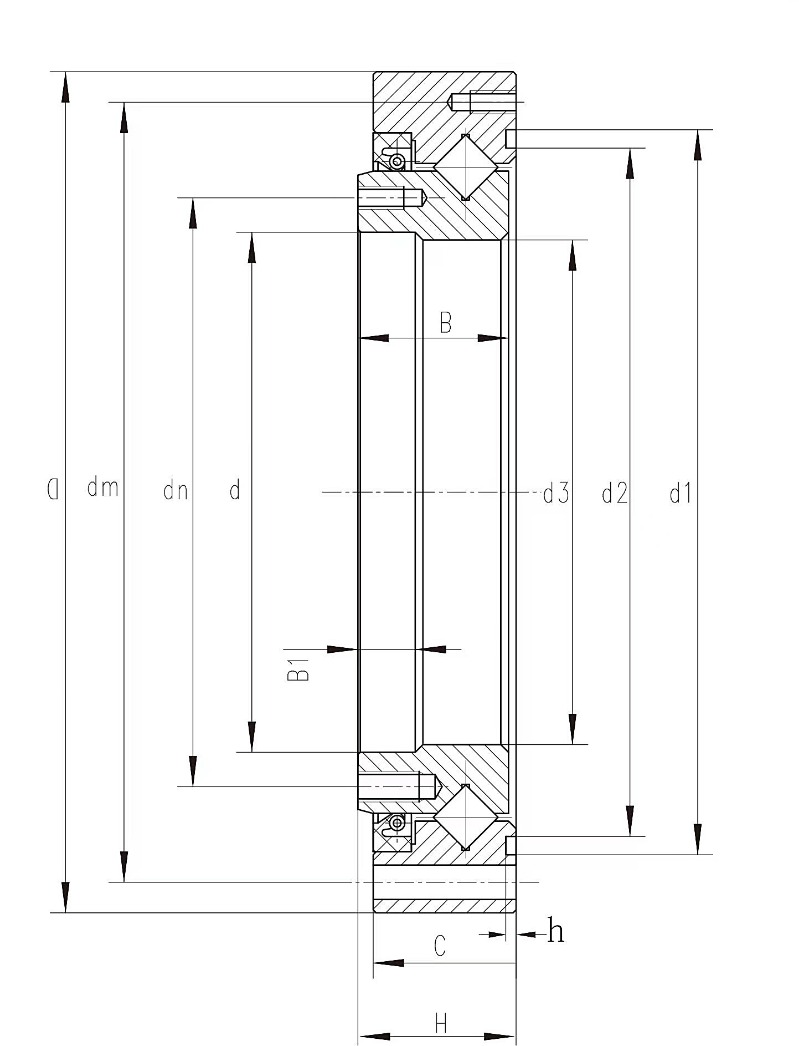

Our harmonic reducer bearings are engineered to provide exceptional rigidity, load-carrying capacity, and precision. These bearings are the critical backbone of harmonic drive systems, which are prized for their high reduction ratios and zero-backlash characteristics. To meet these rigorous standards, FTM utilizes state-of-the-art manufacturing processes and German-imported Marr detection equipment, ensuring every unit meets P2 or P4 precision levels.

Why Choose FTM Harmonic Reducer Bearings

- Customized Engineering: We specialize in non-standard customizations, offering a wide range of materials including Gcr15 bearing steel, 45 steel, and stainless steel.

- Precision Manufacturing: From diameter ranges of 10mm to 25mm, we employ advanced processing technologies such as specialized heat treatment, blackening, and precision threading to enhance durability.

- Rigorous Quality Control: By integrating high-end German metrology, we guarantee that our products serve as reliable import substitutions for high-end machinery.

- Industry Versatility: Our solutions are trusted in robotics, aerospace, and high-precision machine tools, where installation accuracy is non-negotiable.

Technical Specifications and Capabilities

| Feature |

Range and Options |

| Accuracy Grade |

P2, P4 (High Precision) |

| Material Options |

Gcr15, 45 Steel, Stainless Steel, and more |

| Size Range |

Inner Diameter 10mm to 25mm |

| Processing |

Chamfering, Drilling, Grooving, Arc Milling, Electroplating |

| Structural Shapes |

Custom Car Parts, Castings, Forgings |

Frequently Asked Questions (FAQ)

1. What makes FTM harmonic reducer bearings suitable for robotic applications

Robotic joints require smooth motion and high torque density in a small footprint. Our bearings offer the high rigidity and P2/P4 accuracy necessary to minimize positioning errors and ensure fluid movement in multi-axis cobots and industrial robots.

2. How does FTM ensure the precision of its bearings

We utilize imported Marr detectors from Germany to perform comprehensive dimensional and geometric tolerance checks. This ensures that every bearing meets the strict run-out and parallelism requirements demanded by harmonic drive systems.

3. Can FTM provide bearings for harsh environmental conditions

Yes. By utilizing materials like stainless steel and specialized surface treatments such as blackening or electroplating, we can customize bearings to resist corrosion and wear in challenging aerospace or outdoor engineering environments.

4. What is the advantage of FTM as a manufacturer over a standard distributor

As a manufacturer with over 30 years of design experience, we offer direct technical support and the ability to customize the shape and processing of the bearing to fit your specific mechanical housing. This includes custom threading, drilling, and heat treatment protocols.

5. Are these bearings compatible as substitutes for imported brands

Our focus on high-precision R&D allows us to produce bearings that serve as excellent import substitutions. We match or exceed the technical specifications of major global brands, providing a cost-effective and reliable solution for domestic and international high-end markets.

English

English 中文简体

中文简体 عربى

عربى

Download Catalog

Download Catalog