At Shaoxing Shangyu Flight Seiko Machinery Co., Ltd. (FTM), we leverage over 30 years of technical expertise to engineer Single Row Cylindrical Roller Bearings that define reliability and precision. Designed to thrive in demanding environments, these bearings are engineered to manage substantial radial loads while maintaining exceptional performance at high rotational speeds.

The core of our design lies in the linear contact between the cylindrical rollers and the raceways. Unlike standard ball bearings, this configuration ensures optimal load distribution across a larger surface area, significantly reducing stress points and minimizing friction. This makes our bearings an essential component for high-stakes industries including automotive transmissions, aerospace turbines, and heavy industrial machinery.

Why Choose FTM for Your Bearing Solutions

As a specialized manufacturer, FTM goes beyond off-the-shelf products. We bridge the gap between standard requirements and high-precision import substitution.

- Precision Engineering: We offer ultra-high accuracy levels of P2 and P4, ensuring our bearings meet the tightest tolerances required for CNC machinery and high-speed spindles.

- Material Versatility: From standard Gcr15 bearing steel for high durability to stainless steel for corrosion resistance and 45 steel for specific structural needs, we match the material to your environment.

- Advanced Surface Treatments: Our in-house processing includes heat treatment, electroplating, and blackening to enhance wear resistance and longevity.

- Customization and Geometry: Whether you require specific chamfers, threads, grooves, or complex shapes through specialized casting and forging, FTM provides tailor-made mechanical solutions that integrate seamlessly into your assemblies.

Technical Deep Dive: Extended Knowledge

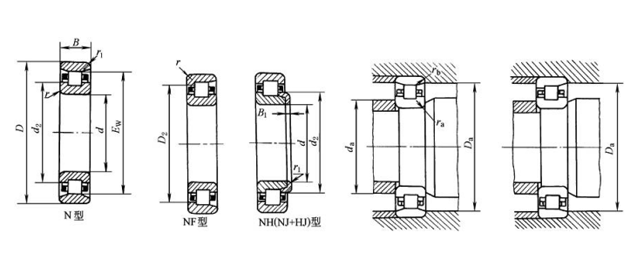

Single row cylindrical roller bearings are classified based on the presence or absence of ribs on the rings (NU, NJ, NUP, or N types). This determines whether the bearing can accommodate axial displacement in both directions, one direction, or act as a locating bearing. At FTM, our technical team works closely with you to determine the ideal configuration for your lubrication system and housing constraints, ensuring maximum thermal stability and service life.

Frequently Asked Questions (FAQ)

1. What is the maximum precision level FTM can provide for these bearings?

FTM specializes in high-precision manufacturing, offering accuracy grades up to P2 and P4. These levels are ideal for applications requiring minimal runout and high rotational accuracy, often serving as high-quality substitutes for expensive imported brands.

2. Can FTM customize bearings for small-scale equipment?

Yes. We offer specialized sizing for smaller applications, with inner diameters ranging from 10mm to 25mm. Despite their compact size, these bearings maintain the high load-bearing characteristics inherent to the cylindrical roller design.

3. What types of specialized processing do you offer for custom orders?

We provide a comprehensive range of secondary operations, including drilling, threading, and the creation of specialized grooves or arcs. We also offer surface finishes like blackening and electroplating to protect against harsh operating conditions.

4. Which industries benefit most from FTM cylindrical roller bearings?

Our products are widely utilized in engineering machinery, textile equipment, and the aerospace sector. Any application involving heavy radial loads and high-speed operation will benefit from our low-friction, high-durability designs.

5. How does FTM ensure the quality of the raw materials used?

We source high-grade Gcr15, stainless steel, and other alloys, subjecting them to rigorous heat treatment processes. Our 30 years of design experience allows us to select and treat materials to ensure they meet the specific fatigue strength and hardness requirements of your project.

English

English 中文简体

中文简体 عربى

عربى

Download Catalog

Download Catalog