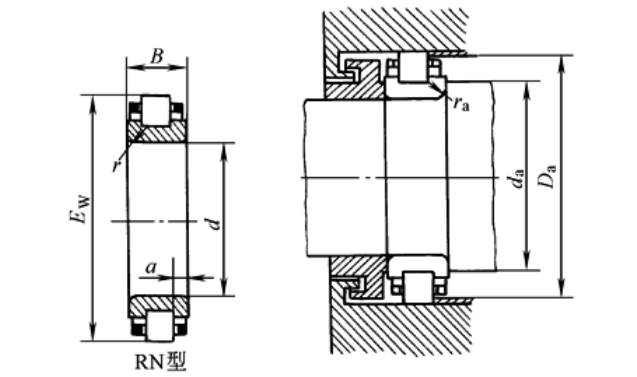

Shaoxing Shangyu Flight Seiko Machinery Co Ltd FTM leverages over 30 years of technical design expertise to offer high precision Cylindrical Roller Bearings without an outer ring. This specialized bearing configuration, consisting only of the inner ring, high grade cylindrical rollers, and a precision engineered cage, is designed for integrated mechanical systems where space efficiency and load density are paramount.

By eliminating the outer ring, the surrounding housing of your equipment functions directly as the outer raceway. This design philosophy significantly reduces the radial cross section, allowing for a more compact and lightweight machine profile. Our FTM technical team ensures that every component is manufactured to rigorous tolerances, ensuring that when paired with a properly machined housing, the assembly achieves maximum rotational accuracy and high radial load capacity.

Why Choose FTM Solutions

As a manufacturer focused on import substitution and non standard customization, FTM provides a distinct advantage in material quality and engineering support. Our bearings are particularly well suited for demanding applications in textile machinery, engineering equipment, and precision gearboxes. We do not just provide a part; we provide a comprehensive bearing solution, ensuring that your housing specifications align perfectly with our bearing tolerances for optimal performance and extended service life.

Key Features and Technical Advantages

- Integrated Space Optimization The absence of the outer ring minimizes the bearing footprint, making it the ideal choice for applications with severe radial space constraints.

- Superior Radial Load Distribution Unlike ball bearings, the line contact of our cylindrical rollers provides a much larger surface area, allowing the bearing to withstand heavy radial forces and shock loads.

- Simplified Design and Assembly Reducing the number of components simplifies your inventory and streamlines the assembly process, while also easing the path for direct lubrication and maintenance.

- Customized Precision FTM specializes in non standard dimensions and specialized cage materials (such as brass, steel, or high performance polymers) to meet specific thermal and speed requirements.

Frequently Asked Questions FAQ

1. What are the surface requirements for the housing used as the outer raceway

Since the rollers contact the housing directly, the internal bore of the housing must be hardened to a level similar to a standard bearing ring (typically HRC 58 to 62) and ground to a precise surface finish (Ra 0.4 or better) to ensure durability and minimize friction.

2. In what specific industries are these bearings most commonly used

These bearings are widely utilized in the textile industry for spinning frames and looms, in automotive transmissions, and in heavy engineering machinery where compact design and high load capacity are critical.

3. Can FTM customize the cage material for high speed applications

Yes. Depending on your operational environment and rotational speeds, we can provide cages made of machined brass for high stability, pressed steel for cost effectiveness, or specialized synthetic materials for reduced weight and noise.

4. How do I ensure proper lubrication for a bearing without an outer ring

Lubrication is often simpler with this design as grease or oil can be applied directly to the roller set. However, the housing design should include proper sealing and lubrication channels to ensure consistent coverage across the raceway surface.

5. Can this bearing handle axial loads

Generally, cylindrical roller bearings are designed to handle radial loads. While some designs with ribs on the inner ring can manage minor axial displacement, they are not intended for significant thrust loads. Our technical team can assist in modifying the design if specific axial constraints are required.

English

English 中文简体

中文简体 عربى

عربى

Download Catalog

Download Catalog