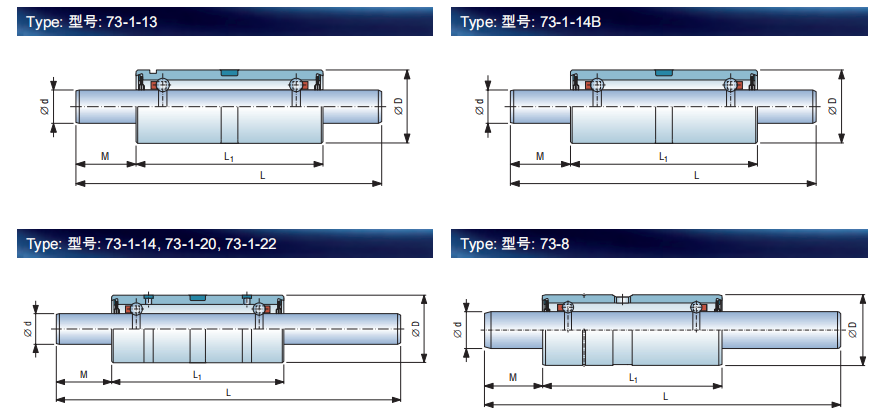

The 73-1-22 Rotor Spindle Bearing is a high-precision composite bearing assembly specifically engineered for the demanding environment of pneumatic textile machinery. As an essential component in open-end spinning systems, this spindle facilitates the high-speed rotation required to twist and wrap fibers into yarn with consistent tension and quality.

Engineered for Extreme Velocity and Durability

Designed to thrive under high-stress conditions, the 73-1-22 model supports a staggering maximum working speed of 72,000 RPM. Its robust internal geometry provides a superior carrying capacity, ensuring that the spindle remains stable even during continuous, long-shift operations.

To maintain peak performance and extend service life, the 73-1-22 features a sophisticated protection system. Dual-end dust grooves and specialized dust rings act as a barrier against debris and fiber lint, while preventing oil leakage. Furthermore, the outer ring is designed with a dedicated oiling channel, allowing for seamless lubrication maintenance to significantly reduce frictional wear.

Technical Specifications

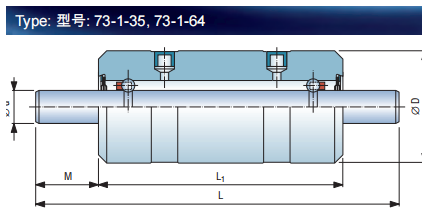

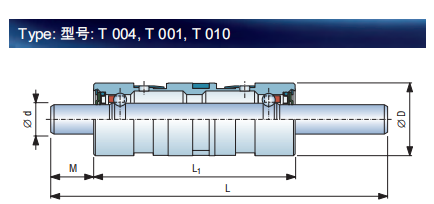

- Outside Diameter D: 22mm

- Shaft Diameter d: 10mm

- Total Length L: 112mm

- Body Length L1: 56mm

- Mounting Width M: 18mm

- Max Speed: 72,000 RPM

The FTM Manufacturing Advantage

With over 30 years of technical expertise, Shaoxing Shangyu Flight Seiko Machinery Co., Ltd. (FTM) provides more than just a standard part. We offer a comprehensive engineering solution:

- Import Substitution Quality: Our bearings are designed to meet or exceed the performance of premium international brands, providing a cost-effective alternative without compromising on precision.

- Advanced Surface Treatments: To combat the abrasive nature of various fibers, we offer specialized plating options for rotors, including Nickel or Diamond-coated finishes for maximum hardness and wear resistance.

- Complete Customization: Beyond the standard 73-1-22 model, FTM can customize internal components such as deep groove ball bearings, shafts, and rings to meet specific torque or load requirements.

- Proven Reliability: Our background in high-precision R&D ensures that every spindle is dynamically balanced to minimize vibration, which is critical for the longevity of both the bearing and the textile machinery.

Frequently Asked Questions (FAQ)

1. Can the 73-1-22 bearing be customized for specific textile machines

Yes. While the 73-1-22 is a standard model, FTM specializes in customization. We can adjust internal clearances, modify shaft lengths, or change the rotor cup material to suit your specific equipment needs.

2. What are the benefits of the diamond-coated rotor option

The diamond-coated surface significantly increases the hardness and reduces the friction coefficient of the rotor. This is particularly beneficial when processing synthetic fibers or high-speed applications where abrasive wear is a concern.

3. How does the lubrication system work in this model

The outer ring is designed with integrated oiling features. This allows technicians to replenish lubricant without disassembling the entire unit, ensuring the bearing remains cooled and lubricated during high-speed rotation.

4. What measures are taken to prevent contamination in textile environments

Textile mills are prone to lint and dust. Our 73-1-22 bearing includes specialized dust rings and grooves at both ends to seal the internal components, preventing debris from entering and oil from escaping.

5. Why choose FTM over other bearing suppliers

FTM brings over three decades of design experience. We focus on non-standard and high-precision bearings, meaning our manufacturing tolerances are tighter than standard industrial grades, resulting in smoother operation and a longer replacement cycle for your machinery.

English

English 中文简体

中文简体 عربى

عربى

Download Catalog

Download Catalog