As a leading manufacturer founded in 2006, Shaoxing Shangyu Flight Seiko Machinery Co., Ltd. (FTM) leverages over 30 years of deep technical design expertise to deliver high-quality bearing solutions. Our Thin Section Ball Bearings are engineered for modern applications where space, weight, and precision are paramount, establishing FTM as a trusted partner for import substitution and non-standard bearing customization.

Product Overview & Key Features

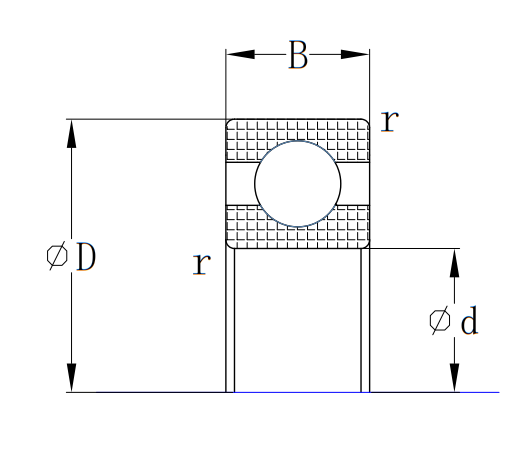

FTM's Thin Section Ball Bearings are designed with an exceptionally small, constant cross-section across a range of bore sizes, offering a unique blend of benefits:

- Space & Weight Reduction: The minimal cross-section significantly reduces the required installation space and overall assembly weight, enabling sleek, compact, and lightweight designs crucial for modern automation.

- High Running Accuracy: Featuring super-finished raceways and high-quality ball components, our bearings ensure extremely smooth rotation, minimizing friction and vibration. This is vital for achieving the high precision required in demanding applications.

- Design Flexibility: Their slim profile often allows for the use of larger diameter shafts or even hollow shafts, providing valuable space for components like wiring, slip rings, or pneumatic lines.

- Load Versatility: Depending on the specific series (e.g., Radial Contact (Type C), Angular Contact (Type A), or Four-Point Contact (Type X)), our thin section bearings are capable of handling combined radial, axial, and moment loads effectively.

Expanded Applications: Where Precision Matters Most

The lightweight and high-precision characteristics make FTM's thin section bearings indispensable in various cutting-edge industries, including but not limited to:

- Robotics & Automation: Critical components in robot arms, robot speed reducers, harmonic drives, and RV gearboxes, facilitating precise and efficient joint movement.

- Aerospace & Instrumentation: Used in astronomy instrumentation, satellite systems, and optical equipment where weight saving and high reliability are non-negotiable.

- High-End Manufacturing: Integrated into machine tools, textile machinery, and semiconductor manufacturing equipment to ensure smooth and accurate operation.

- Automotive: Applied in components like automobile drive gears and other precision systems.

Manufacturer's Advantage: The FTM Difference

Choosing FTM means partnering with a specialist in high-end, customized bearing technology:

- 30+ Years of Technical Design: Our seasoned technical team provides unparalleled expertise, translating decades of experience into meticulously engineered, high-performance bearings.

- Customization Expertise: Beyond standard sizes, FTM excels in the R&D and customization of non-standard and high-precision bearings. We can tailor material, lubrication, seal/shield type, clearance, and precision grades (e.g., up to ABEC 7/ISO P4) to perfectly meet your unique performance requirements.

- Import Substitution Capability: We are dedicated to delivering bearings that meet or exceed the quality and performance standards of imported high-precision bearings, offering a reliable, cost-effective alternative for the global market.

- Holistic Solution Provider: We don't just supply parts; we provide high-quality bearing solutions to complex engineering challenges in diverse fields.

Thin Section Ball Bearing: 5 Essential FAQs

Q: What are the three primary types of Thin Section Ball Bearings?

A: Radial Contact (Type C) for radial loads, Angular Contact (Type A) for high thrust loads, and Four-Point Contact (Type X) for moment and reversing loads.

Q: How does FTM ensure high running accuracy?

A: By using super-finished raceways, selecting high-quality ball complements, and maintaining strict precision tolerances throughout manufacturing.

Q: Are these bearings only for low-speed applications?

A: No. While their design is compact, FTM's precision bearings are engineered for highly flexible performance and are suitable for applications requiring high running speeds where appropriate.

Q: What is FTM's "import substitution" capability?

A: It means FTM manufactures high-precision bearings that meet or exceed the quality and performance standards of major international brands, providing a reliable, cost-effective alternative.

Q: Can FTM customize bearings for unique environments (e.g., high temp/vacuum)?

A: Yes. We specialize in customization, adjusting materials, lubricants (e.g., vacuum grease), and configurations to meet specific environmental and performance requirements.

English

English 中文简体

中文简体 عربى

عربى

Download Catalog

Download Catalog