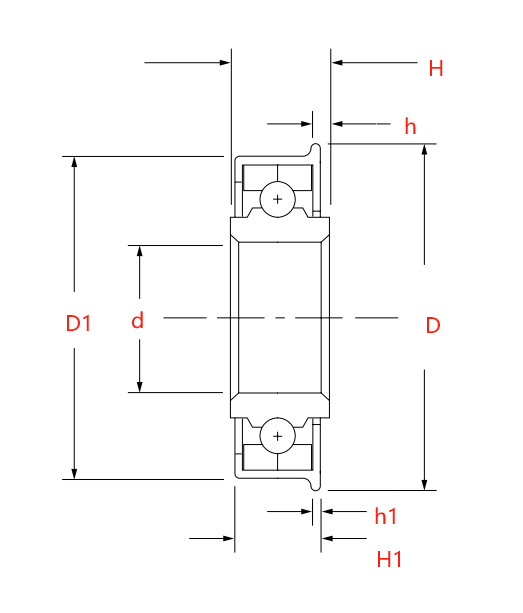

Shaoxing Shangyu Flight Seiko Machinery Co., Ltd. (FTM) specializes in providing high-performance, cost-effective solutions for diverse industrial applications. Our Unground Flanged Ball Bearings represent a perfect synergy of structural integration and economic efficiency. By combining the flange and the bearing into a single unit, these bearings simplify the mounting process, particularly when a shaft needs to be secured against a flat surface like a mounting plate or a machine wall.

While standard precision bearings require intensive grinding processes, our Unground series focuses on delivering reliable performance in applications where ultra-high precision is not the primary requirement. This makes them an ideal choice for high-volume industries looking to optimize their budget without compromising on durability or functionality.

Technical Advantages and Applications

Our Unground Flanged Ball Bearings are engineered to reduce friction and enhance rotation accuracy in various mechanical assemblies. The integrated flange acts as a built-in housing, preventing axial movement and ensuring the bearing stays locked in position under vibration or operational stress.

Key Application Fields

- Transmission Equipment: Ideal for conveyor rollers and light-duty drive systems.

- Textile Machinery: Perfect for auxiliary rotating parts where cost-efficiency is paramount.

- Robotics and Automation: Used in robotic arm joints and positioning sensors.

- Electric Motors: Facilitates smooth rotation in small to medium-sized motor assemblies.

Why Choose FTM as Your Manufacturing Partner

With over 30 years of technical design experience, FTM goes beyond standard manufacturing. We understand that non-standard requirements are the norm in modern engineering.

- Tailored Customization: We offer full customization of dimensions, load capacities, and specialized materials to meet your specific environmental challenges.

- Import Substitution Expertise: Our R and D team excels at creating local alternatives for expensive imported bearings, maintaining quality while reducing your lead times.

- Quality Assurance: Leveraging our heritage in high-precision bearing design, even our Unground series benefits from rigorous quality control and expert engineering oversight.

Frequently Asked Questions

1. What is the primary difference between a ground and an unground bearing?

Ground bearings undergo a precision grinding process on the races to achieve tight tolerances and high speeds. Unground bearings are machined or cold-formed, offering a significantly lower price point while remaining perfectly suitable for moderate speed and load applications.

2. Can FTM produce these bearings in stainless steel or specialized alloys?

Yes. FTM provides material customization. Depending on your working environment, such as exposure to moisture or chemicals, we can manufacture these bearings using stainless steel or other corrosion-resistant materials.

3. In what specific mounting scenario is a flanged bearing most useful?

A flanged bearing is most beneficial when the housing lacks a shoulder to stop the bearing or when the bearing must be mounted through a sheet metal wall or a thin plate. The flange provides a secure mechanical stop.

4. Does the unground nature of the bearing affect its service life?

Not necessarily. While they are not intended for high-speed precision spindles, when used within their rated load and speed parameters, unground bearings offer excellent durability and a long service life in many industrial and consumer products.

5. Is there a minimum order quantity for customized sizes?

As a flexible manufacturer, FTM caters to both standard batch production and customized non-standard orders. Please contact our technical team with your specific dimensions and volume requirements for a tailored quote.

English

English 中文简体

中文简体 عربى

عربى

Download Catalog

Download Catalog